When it comes to plush toys, nothing beats that irresistibly soft touch that brings comfort and joy to all ages. But what exactly defines the softest plush toy fabric, and why does it matter so much to manufacturers, retailers, and consumers? In the plush toy industry, softness isn’t just a feel-good feature—it’s a key factor driving customer satisfaction and product success.

The softest plush toy fabrics typically include minky, velboa, and fleece, prized for their ultra-fine fibers and smooth textures. These materials combine comfort, durability, and safety, making them the top choices for high-quality plush toys.

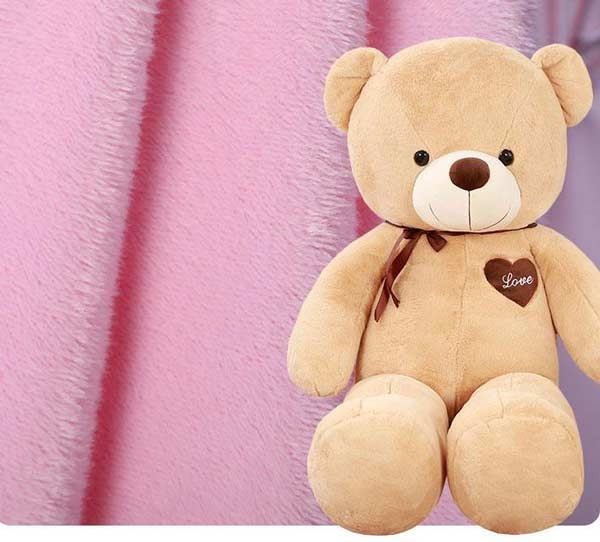

Imagine a child clutching a plush bear so soft it almost feels like a warm hug — that magic starts with the fabric. But softness alone isn’t enough; choosing the right fabric involves balancing texture, durability, safety, and sustainability. Let’s dive into the fabrics that make your favorite plushies so cuddly and explore how manufacturers create these soft sensations.

1. What Types of Fabrics Are Commonly Used for Plush Toys?

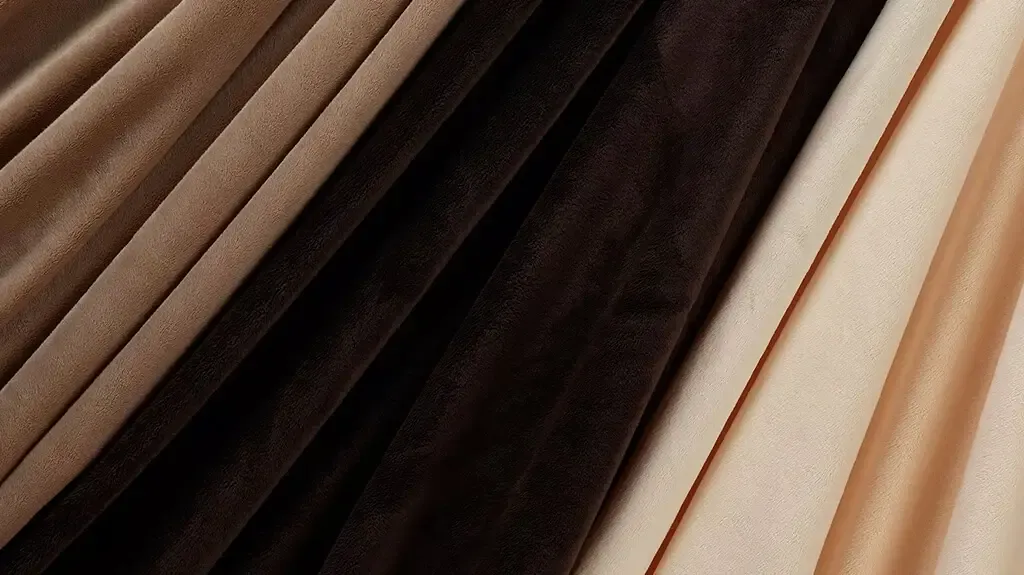

Plush toys commonly use fabrics like polyester-based minky, velboa, fleece, and cotton blends, with each offering different softness, durability, and aesthetic qualities.

Exploring Plush Toy Fabric Varieties

- Synthetic vs. Natural Fibers: Synthetic fabrics like polyester are favored for their softness and durability, while natural fibers such as cotton offer breathability but often lack longevity. Polyester dominates the market due to cost-effectiveness and versatility.

- Minky Fabric: Known for its ultra-soft texture, minky features a dense pile that creates a velvety feel. It’s popular for baby toys and luxury plush.

- Velboa Fabric: Slightly shorter pile than minky, velboa is soft, smooth, and often used in affordable plush toys without compromising comfort.

- Fleece: Provides a warm, fuzzy surface with excellent stretch and softness, often used in stuffed animals requiring flexibility.

- Cotton and Cotton Blends: Less common in plush toys due to lower durability, but appreciated for natural feel and hypoallergenic properties.

Many premium plush toys use minky fabric on the exterior for softness, with polyester fiberfill stuffing for resilience, creating a perfect balance.

| Fabric Type | Material Base | Softness Level | Durability | Common Uses | Key Features |

|---|---|---|---|---|---|

| Minky | Polyester | Ultra-soft, velvety | Medium | Baby toys, luxury plush | Dense pile, very soft texture |

| Velboa | Polyester | Soft, smooth | High | Affordable plush toys | Shorter pile than minky, good comfort and durability |

| Fleece | Polyester blends | Warm, fuzzy | Medium | Flexible stuffed animals | Excellent stretch, softness, warmth |

| Cotton & Blends | Natural fibers | Moderate | Lower | Specialty plush, hypoallergenic | Natural feel, breathable, less durable |

2. Which Plush Toy Fabrics Are Considered the Softest?

Minky, velboa, and high-quality fleece fabrics are widely recognized as the softest due to their fine fibers and plush textures.

The Science Behind Softness

- Fiber Thickness and Length: Finer, longer fibers result in softer textures; minky typically has fibers 3-4 mm long, giving it a plush, cloud-like feel.

- Fabric Weave and Density: Tightly woven fabrics with dense piles trap more air, enhancing softness and warmth.

- Finish and Treatment: Post-production treatments, like brushing or shearing, refine surface texture, making fabric feel smoother.

- Comparing Fabrics: For example, velboa is less plush than minky but offers better durability, suitable for active play. Fleece offers warmth but with less luxurious softness compared to minky.

Comparison of Soft Plush Fabrics

| Fabric Type | Fiber Length (mm) | Texture Description | Durability | Typical Use Cases |

|---|---|---|---|---|

| Minky | 3.5 – 4 | Ultra-soft, velvety | Medium | Baby toys, luxury plush |

| Velboa | 1.5 – 2 | Smooth, soft | High | Affordable plush toys |

| Fleece | 2 – 3 | Fuzzy, warm | Medium | Flexible plush toys |

3. How Does Fabric Softness Affect Plush Toy Durability and Safety?

Softer fabrics may be more delicate, but with proper manufacturing and quality controls, they can meet durability and safety standards for children’s toys.

Balancing Softness, Durability, and Safety

- Wear and Tear: Ultra-soft fabrics like minky have a higher risk of pilling or fiber loss with heavy use. Manufacturers mitigate this with dense weaving and quality finishing.

- Safety Standards: Plush fabrics must be tested for flammability, non-toxicity, and hypoallergenic qualities. Softer fabrics often require additional treatments to meet safety regulations.

- Cleaning and Maintenance: Some soft fabrics can degrade if washed improperly, affecting longevity and safety. Using machine-washable fabrics with robust finishes improves consumer satisfaction.

- Case Study: Leading plush manufacturers use velboa for children’s toys because it balances softness and durability, passing rigorous ASTM and EN71 safety tests.

| Factor | Impact on Softness | Mitigation / Solution | Example / Note |

|---|---|---|---|

| Wear and Tear | Softer fabrics like minky pill or lose fibers faster | Use dense weaving and quality finishing | Dense weave reduces pilling, extends lifespan |

| Safety Standards | Softer fabrics may need extra treatment for safety | Test for flammability, non-toxicity, hypoallergenic | Velboa meets ASTM and EN71 standards for children’s toys |

| Cleaning & Maintenance | Improper washing can degrade softness and durability | Use machine-washable fabrics with robust finishes | Consumer satisfaction improves with easy-care fabrics |

4. Do Eco-Friendly and Sustainable Fabrics Offer Comparable Softness?

Yes, sustainable fabrics like organic cotton blends and recycled polyester can offer softness comparable to conventional materials but may require innovative processing techniques.

Sustainability in Plush Fabric Production

- Organic Cotton: Naturally soft and breathable, organic cotton appeals to eco-conscious consumers but may lack plush density found in synthetic fibers.

- Recycled Polyester: Increasingly popular, recycled fibers maintain softness and durability while reducing environmental impact. Innovations in fiber processing have improved softness quality significantly.

- Biodegradable Plush Fabrics: Emerging materials like bamboo blends offer softness and sustainability but are not yet mainstream due to cost and manufacturing complexity.

- Challenges: Sustainable fabrics often cost more and require certification (e.g., GOTS, OEKO-TEX) to assure consumers of their eco-credentials.

- Example: Brands incorporating recycled polyester plush fabric in toys show competitive softness while reducing plastic waste.

| Sustainable Fabric Type | Softness Level | Environmental Benefits | Challenges | Notes / Examples |

|---|---|---|---|---|

| Organic Cotton | Naturally soft, breathable | Grown without harmful pesticides | Lower plush density, higher cost | Popular among eco-conscious consumers |

| Recycled Polyester | Comparable to conventional polyester | Reduces plastic waste, energy saving | Processing complexity, certification required | Used by brands aiming for eco-friendly plush |

| Biodegradable Fabrics (e.g., Bamboo blends) | Soft and sustainable | Biodegradable, renewable resource | High cost, limited manufacturing scale | Emerging option, not yet mainstream |

5. Is Fabric Softness the Only Factor Buyers Consider When Choosing Plush Toys?

No, buyers also consider hypoallergenic properties, ease of cleaning, aesthetic appeal, and safety certifications alongside fabric softness.

Comprehensive Buyer Priorities

- Hypoallergenic Features: Essential for baby products; fabrics that resist dust mites and allergens increase buyer trust.

- Cleaning Convenience: Machine-washable plush fabrics are preferred for longevity and hygiene.

- Visual and Tactile Appeal: Fabric color, sheen, and texture affect emotional connection; some buyers prioritize looks over pure softness.

- Price Sensitivity: Softer fabrics like minky often cost more, so buyers balance softness with budget.

- Cultural and Regional Preferences: Different markets prefer different plush textures—Asia favors ultra-soft kawaii fabrics, while Western markets may prioritize durability.

| Buyer Consideration | Description | Impact on Purchase Decision | Example / Note |

|---|---|---|---|

| Hypoallergenic Features | Fabrics that resist dust mites and allergens | Builds trust, especially for baby products | Essential for infant plush toys |

| Cleaning Convenience | Preference for machine-washable fabrics | Enhances longevity and hygiene | Buyers favor easy-care plush toys |

| Visual and Tactile Appeal | Color, sheen, and texture influence emotional connection | May outweigh softness in some markets | Kawaii-style plushes emphasize look and feel |

| Price Sensitivity | Balancing softness with budget constraints | Buyers may choose less soft but affordable fabrics | Minky is softer but often more expensive |

| Cultural and Regional Preferences | Varying texture preferences by region | Influences product design and fabric selection | Asia prefers ultra-soft; West prioritizes durability |

6. How Can Manufacturers Balance Softness with Production Efficiency and Cost?

Manufacturers use advanced fabric treatments, optimized weaving techniques, and material blends to deliver softness cost-effectively while maintaining production speed.

Manufacturing Innovations and Strategies

- Fabric Blends: Combining polyester with cotton or rayon can reduce costs while retaining softness.

- Finishing Techniques: Brushing, shearing, and calendaring enhance softness post-weaving without expensive raw materials.

- Automation: Modern knitting and weaving machines produce dense plush fabrics efficiently, reducing labor costs.

- Sourcing Strategies: Bulk purchasing of high-quality synthetic fibers enables competitive pricing.

- Quality Control: Continuous testing ensures softness isn’t sacrificed for speed or cost-cutting.

- Example: Kinwin’s factory integrates digital fabric inspection and precise finishing to ensure every plush toy fabric meets softness and durability standards.

| Strategy | Description | Benefit | Example / Note |

|---|---|---|---|

| Fabric Blends | Mixing polyester with cotton or rayon | Lowers cost while maintaining softness | Cost-effective yet soft plush fabrics |

| Finishing Techniques | Brushing, shearing, calendaring post-weaving | Enhances softness without expensive raw materials | Improves fabric feel efficiently |

| Automation | Use of modern knitting and weaving machines | Increases production speed, reduces labor cost | Produces dense, consistent plush fabric |

| Sourcing Strategies | Bulk purchasing of quality synthetic fibers | Competitive pricing, stable material supply | Enables cost control and quality consistency |

| Quality Control | Continuous softness and durability testing | Ensures no compromise between speed, cost, and quality | Kinwin’s digital inspection guarantees standards |

Ready to Elevate Your Plush Toy Line with the Softest Fabrics?

Softness is a key selling point for plush toys, but balancing it with durability, safety, sustainability, and cost is what makes a truly successful product. At Kinwin Plush Toy Factory, we specialize in crafting premium, eco-friendly, and ultra-soft plush fabrics tailored to your unique designs and market needs.

Whether you need luxurious minky for baby toys or durable velboa for everyday plush companions, our advanced production capabilities and strict quality control guarantee excellence.

Contact Kinwin today for a personalized consultation and custom plush fabric solutions that will delight your customers and stand out in the market. Let’s create the softest, safest, and most beautiful plush toys together!