Sewing a stuffed animal requires skillful techniques, careful fabric selection, and attention to detail. Each step shapes the toy’s durability and charm.

Key sewing techniques for plush toys include precise stitching, fabric choice, and careful assembly. Even stuffing distribution and quality finishing ensure a soft, durable toy. Troubleshooting common issues improves final product quality, essential for satisfying buyers worldwide.

Let’s dive into the sewing process and explore how to create lovable, lasting stuffed animals.

1.What basic sewing techniques are essential for constructing stuffed animals?

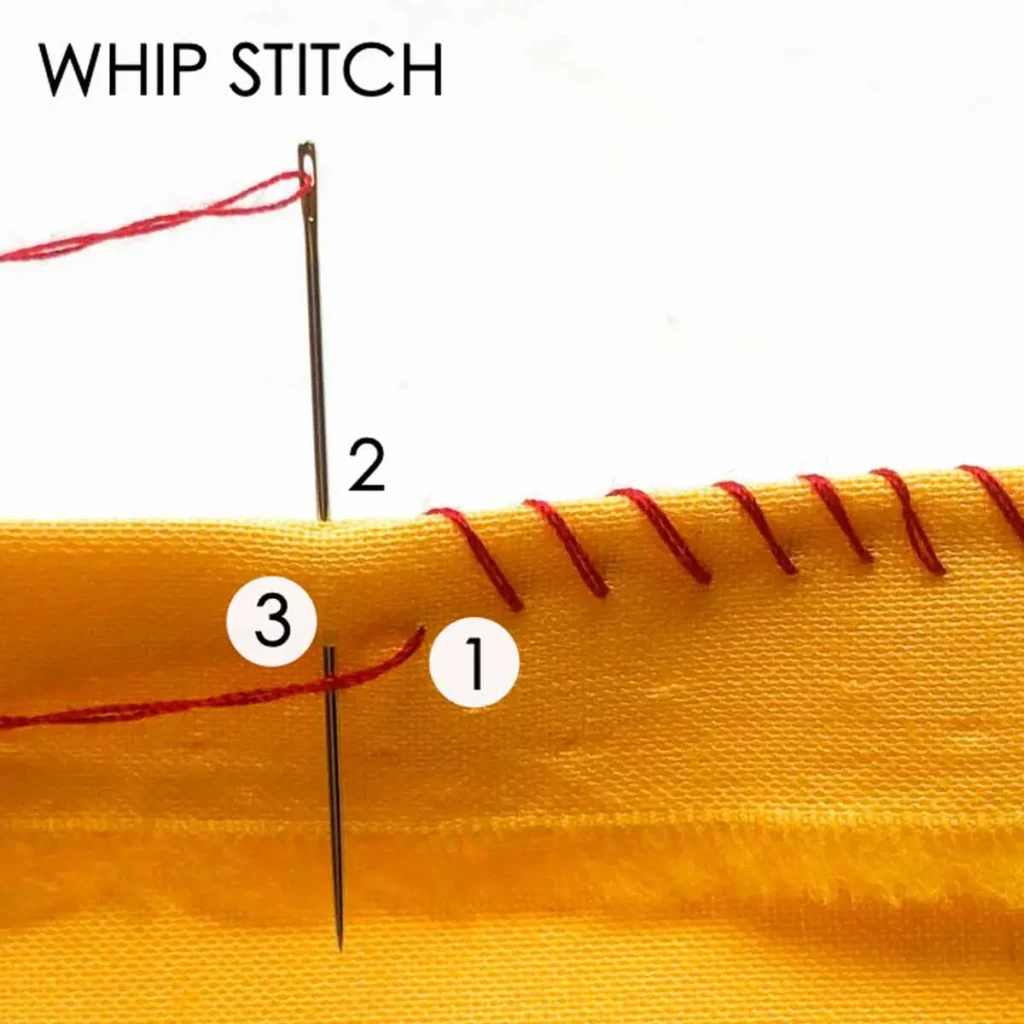

Constructing a stuffed animal starts with mastering stitches that secure pieces while maintaining soft edges. Common techniques balance strength and appearance.

Essential sewing techniques include lockstitch for seams, ladder stitch for closing, and backstitch for reinforcement. These ensure strong, neat construction for plush toys.

Lockstitch is the most common machine stitch used for joining plush fabric pieces. It creates durable seams that hold stuffing firmly inside. Backstitch, a hand stitch, reinforces stress points like limbs or joints, preventing tearing during play.

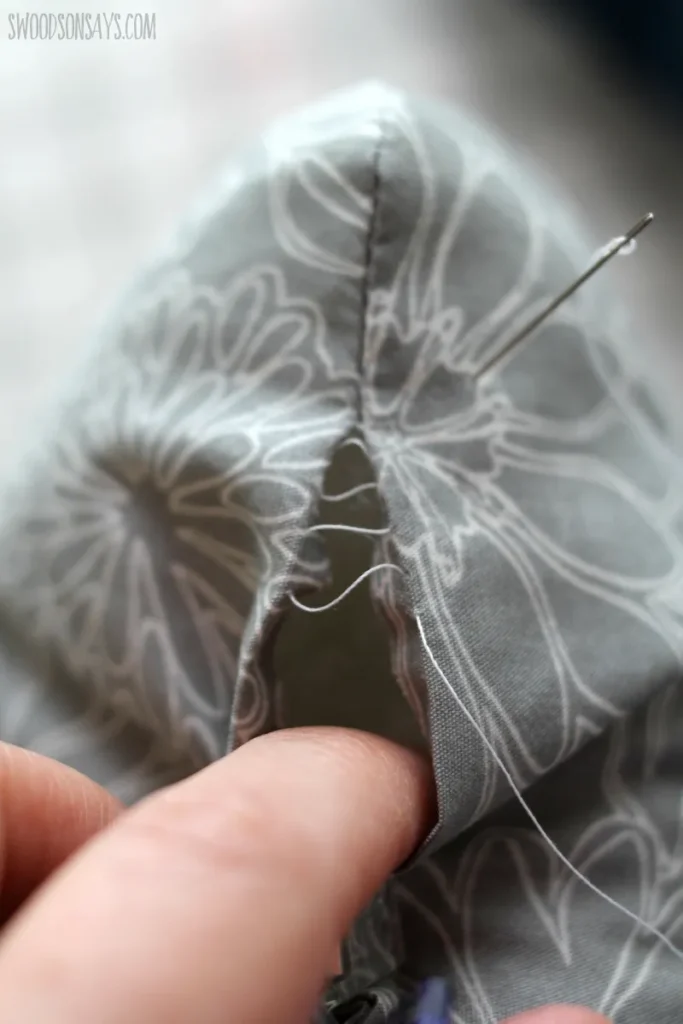

Ladder stitch (also called invisible stitch) is crucial for closing openings after stuffing. It hides stitches beneath the fabric surface, leaving a neat finish without visible seams.

Mastering tension control on sewing machines prevents puckering or loose threads. Consistent stitch length, usually 2-3 mm, maintains seam integrity and appearance.

| Stitch Type | Usage | Benefits |

|---|---|---|

| Lockstitch | Joining main fabric pieces | Strong, clean seams |

| Backstitch | Reinforcing high-stress areas | Prevents seam failure |

| Ladder stitch | Closing stuffing openings | Invisible, tidy finish |

By combining these techniques, plush toys gain structural strength and a professional look.

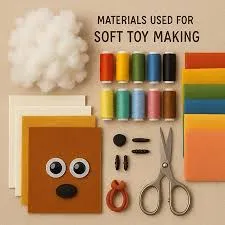

2.How do you select appropriate fabrics and threads for plush toy sewing?

Choosing soft, durable fabrics and matching thread quality is key to making safe and appealing stuffed animals.

Polyester plush or minky fabrics with strong polyester thread are ideal. Materials should be hypoallergenic, tear-resistant, and safe for children.

Plush toy fabric must feel soft yet withstand regular play. Polyester plush and minky fabrics meet these demands, providing a cuddly texture that holds shape.

Thread selection is equally important. Polyester thread offers elasticity and strength, matching the fabric’s durability. Using a thread color close to fabric reduces visible stitching, improving aesthetics.

Fabrics and threads must comply with safety standards like ASTM and CE, ensuring non-toxicity and hypoallergenic properties. This is critical for global markets and customer trust.

| Material | Properties | Suitability |

|---|---|---|

| Polyester plush | Soft, durable, washable | General plush toy surface |

| Minky fabric | Very soft, textured | Premium plush toys |

| Polyester thread | Strong, slightly elastic | Seams with stretch and strength |

Selecting fabrics and threads carefully improves toy quality and customer satisfaction.

3.What are the step-by-step procedures to assemble and sew stuffed animal parts?

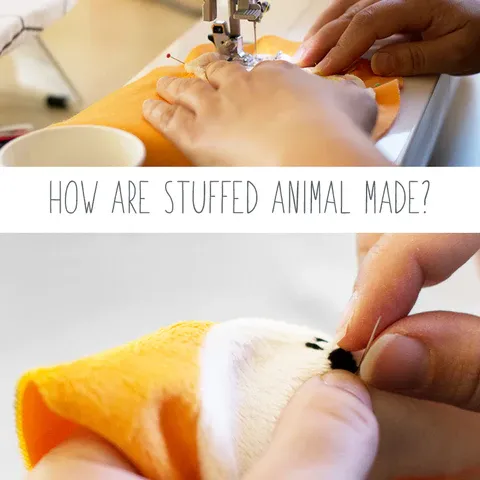

Assembling plush toys requires precise cutting, aligning, and sewing parts in correct order for proper shape and function.

Cut fabric per patterns, sew pieces right sides together, leave opening for stuffing, then turn inside out. After stuffing, close the opening with ladder stitch.

The assembly starts by cutting fabric parts using well-designed patterns, ensuring accuracy and symmetry.

Next, sew pieces together with right sides facing each other, leaving openings for turning and stuffing. Commonly, limbs, ears, and tails are sewn separately before attaching to the body.

After sewing, turn pieces inside out to hide seams and prepare for stuffing. Carefully insert stuffing to fill all corners, shaping the toy correctly.

Once fully stuffed, close the opening with a ladder stitch, which creates an invisible seam, maintaining the plush toy’s clean appearance.

| Step | Description | Tips |

|---|---|---|

| Cutting | Use sharp scissors or cutting tools | Follow pattern precisely |

| Sewing pieces | Join fabric right sides together | Leave stuffing openings |

| Turning inside out | Hide seams | Use tools to push out corners |

| Stuffing | Insert fiberfill evenly | Avoid lumps, shape carefully |

| Closing | Use ladder stitch | Keep seam invisible and strong |

Following these steps ensures a well-constructed plush toy with a smooth finish.

4.How can stuffing be evenly distributed while maintaining shape and softness?

Even stuffing keeps the toy cuddly and well-shaped, avoiding lumps and flat spots that reduce appeal.

Stuff small sections gradually, push stuffing into corners, and balance firmness with softness for a natural, durable shape.

Proper stuffing technique is as important as material choice. Begin by adding small amounts to one section, working slowly to fill all areas without overstuffing.

Use tools like chopsticks or stuffing sticks to push fiberfill into tight spots like limbs and ears. This ensures no empty pockets remain.

Balancing softness and firmness involves layering stuffing more densely in structural areas like heads and limbs, while leaving the body softer for cuddling comfort.

Too much stuffing stresses seams; too little leads to sagging. Consistency enhances durability and user satisfaction.

| Stuffing Tip | Purpose | Result |

|---|---|---|

| Gradual stuffing | Control fill level | Prevents lumps |

| Use tools | Reach tight corners | Full shape retention |

| Layering | Firm areas vs. soft zones | Balanced plushness |

Correct stuffing techniques increase toy quality and longevity.

5.Which finishing stitches and details enhance durability and appearance?

Final stitching and small details create a lasting impression, reinforcing weak points and adding charm.

Finishing touches like double stitching, embroidery, and securely attached features enhance plush toy strength and visual appeal.

Double stitching around joints or limbs strengthens areas prone to stress. It prevents seam splitting, extending toy life.

Embroidered features like eyes or mouths replace plastic parts to improve safety and durability. Where plastic eyes are used, ensure secure attachments with backing washers.

Adding decorative details such as bows or clothing requires careful stitching to avoid loose parts. All accessories must withstand typical play stresses.

Final inspection checks include verifying stitch consistency, trimming excess threads, and confirming secure attachments.

| Finishing Detail | Benefit | Customer Value |

|---|---|---|

| Double stitching | Reinforces seams | Longer-lasting toys |

| Embroidery | Safe, durable facial features | Enhanced safety and design |

| Secure accessories | Prevent choking hazards | Child safety compliance |

These details ensure plush toys remain safe, attractive, and reliable for end users.

6.How do you troubleshoot common sewing challenges in plush toy making?

Addressing sewing issues promptly improves production efficiency and product quality.

Common challenges include fabric puckering, uneven seams, and thread breakage. Solutions involve adjusting machine tension, using proper needles, and training staff.

Fabric puckering happens when sewing tension is too high or fabric isn’t properly stabilized. Lowering machine tension or using stabilizers helps.

Uneven seams often result from inconsistent fabric feeding. Training operators on fabric handling and using walking foot machines improves seam quality.

Thread breakage may arise from incorrect needle size or low-quality thread. Matching needle type to fabric and using strong polyester thread prevents breaks.

Regular machine maintenance ensures smooth operation, reducing defects.

| Problem | Cause | Solution |

|---|---|---|

| Fabric puckering | High tension, unstable fabric | Adjust tension, use stabilizers |

| Uneven seams | Poor fabric control | Operator training, walking foot |

| Thread breakage | Wrong needle, poor thread | Use correct needle, quality thread |

| Machine malfunction | Lack of maintenance | Scheduled servicing |

Proactive troubleshooting leads to consistent, high-quality plush toy production.

Conclusion

Mastering sewing techniques and materials creates soft, durable stuffed animals that delight customers worldwide.

For reliable plush toy manufacturing, contact Amanda at [[email protected]] or visit [https://plushtoyinchina.com].