Making a stuffed animal is a careful process combining creativity, quality materials, and precise techniques. Each step affects the toy’s softness, safety, and appeal.

Creating a stuffed animal involves selecting safe materials, designing patterns, choosing the right stuffing, stitching with care, ensuring quality control, and allowing customization. Every stage matters to deliver a durable, soft, and lovable product that meets market needs and safety standards.

Let’s explore the detailed steps involved in producing a high-quality stuffed animal.

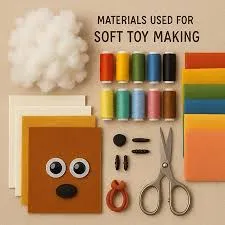

1.What are the essential materials and tools required for stuffed animal production?

To make a plush toy, you need the right fabrics, stuffing, sewing supplies, and safety components. These basics ensure the toy’s look, feel, and safety.

Essential materials include soft plush fabric, hypoallergenic stuffing, thread, needles, and safety eyes or noses. Tools like sewing machines, scissors, and pattern templates support efficient production.

The choice of materials is critical for producing stuffed animals that appeal to customers like Jessica Williams, who prioritize safety and quality. Common materials include:

- Fabric: Polyester plush or microfiber is soft, durable, and safe for children.

- Stuffing: Polyester fiberfill is hypoallergenic and maintains shape well.

- Thread and Needles: High-quality, strong thread and suitable needles ensure secure stitching.

- Safety Components: Plastic safety eyes, noses, and sometimes embroidered features, comply with safety standards like ASTM and CE.

Tools needed include industrial sewing machines for volume production, cutting tools for fabric shaping, and pattern templates to guide design accuracy.

| Material/Tool | Purpose | Key Features |

|---|---|---|

| Plush Fabric | Soft exterior | Durable, hypoallergenic |

| Polyester Fiberfill | Core stuffing | Lightweight, resilient |

| Thread & Needles | Joining fabric parts | Strong, color-matched |

| Safety Eyes/Noses | Toy facial features | Child-safe, securely attached |

| Sewing Machines | Efficient stitching | Adjustable speed and stitch types |

| Pattern Templates | Guide cutting and shaping | Precise, repeatable |

Choosing the right combination ensures safety, durability, and customer satisfaction.

2.How do designers create and refine patterns for plush toy prototypes?

Designers translate ideas into patterns, which are templates for cutting fabric pieces. Refining patterns ensures the final toy looks and fits together perfectly.

Patterns are drawn based on sketches, then cut and sewn into prototypes. Designers adjust patterns for shape, size, and seam placement to optimize fit and appearance.

Creating a plush toy pattern starts with concept sketches. Designers then create 2D patterns that represent each piece of fabric needed. These patterns guide cutting and sewing.

The first prototype often reveals issues like awkward shapes or seam tension. Designers tweak the pattern by adding or removing seam allowances, adjusting curves, or resizing parts.

Digital tools like CAD software can speed up this process, allowing precise measurements and quick revisions. Still, hands-on prototype testing remains essential for feel and fit.

| Step | Description | Purpose |

|---|---|---|

| Sketching | Initial design ideas | Visual concept |

| Pattern Drafting | Creating 2D fabric templates | Cutting guidance |

| Prototype Sewing | Making sample plush toy | Test fit and appearance |

| Pattern Adjustment | Refining shape and seam lines | Improve fit and durability |

This cycle repeats until the prototype meets design and functional goals.

3.Which stuffing types and techniques ensure optimal softness and durability?

Stuffing affects the toy’s feel, shape retention, and safety. Proper techniques prevent lumps and help toys withstand play.

Polyester fiberfill is common stuffing, offering softness and durability. Even distribution and layering techniques ensure consistent plushness and structural support.

Choosing stuffing material involves balancing softness and resilience. Polyester fiberfill is lightweight, hypoallergenic, and maintains shape well. Alternatives like foam or beads add weight or texture but suit different product types.

Stuffing technique matters as much as material. Workers carefully insert fiberfill, pushing into corners to avoid empty spaces. Layering is used for body parts needing firmness, such as limbs or heads, while other areas remain soft.

Overstuffing can stress seams; understuffing makes toys floppy. Proper stuffing also aids durability, preventing deformation after repeated use.

| Stuffing Type | Characteristics | Application |

|---|---|---|

| Polyester Fiberfill | Soft, lightweight, washable | General plush toys |

| Foam Inserts | Firm, supportive | Structured or weighted parts |

| Plastic Pellets | Adds weight, texture | Bottom weighting or sensory toys |

Good stuffing ensures plush toys stay inviting and durable, matching customer expectations.

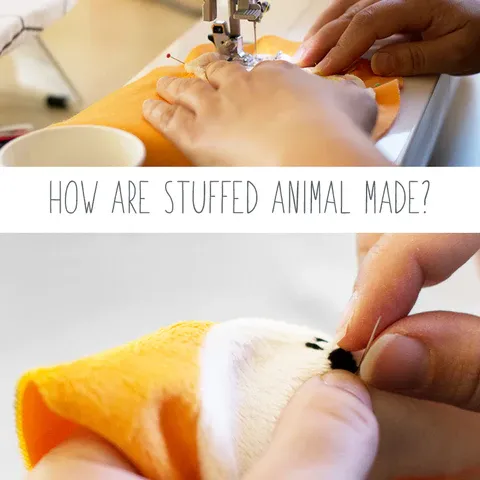

4.How is stitching executed to balance aesthetics and structural integrity?

Stitching holds the toy together and shapes it. Quality stitching prevents tearing while keeping seams neat and attractive.

Strong, even stitching with double seams is ideal. Invisible or decorative stitches enhance appearance while ensuring durability.

Sewing plush toys involves choosing the right stitch type and tension. A tight, even stitch keeps seams secure under stress. Double or reinforced stitching at joints prevents splitting during play.

Invisible stitching, like ladder stitch, is used to close openings after stuffing, giving a clean look. Decorative stitches add character without compromising strength.

Automated sewing machines increase efficiency but require skilled operators to avoid uneven stitches that weaken seams.

| Stitch Type | Purpose | Advantages |

|---|---|---|

| Lockstitch | Standard seam stitching | Durable, clean finish |

| Double Stitch | Reinforced seams | Extra strength at stress points |

| Ladder Stitch | Closing stuffing openings | Invisible, neat |

Balancing appearance and strength is essential for long-lasting, attractive toys.

5.What quality control measures are critical during manufacturing?

Strict inspections ensure each toy meets safety, quality, and customer standards before shipping.

Quality control includes checking materials, stitching, stuffing, and safety components to meet certifications and prevent defects.

Quality control (QC) begins with raw material inspection, verifying fabric softness and safety certificates. During production, workers inspect seams and stuffing consistency.

Finished toys undergo testing for choking hazards, colorfastness, and seam strength. Compliance with ASTM and CE standards is verified, especially for export markets.

Regular QC audits, sampling, and batch tracking minimize defects and build trust with clients like Jessica Williams.

| QC Stage | Focus Area | Typical Checks |

|---|---|---|

| Raw Materials | Safety and quality certificates | Fabric test, color, texture |

| In-Process QC | Stitching, stuffing consistency | Seam strength, uniform stuffing |

| Final Inspection | Overall safety and appearance | Safety parts, labeling, defects |

Effective QC ensures reliable, safe products that satisfy buyer demands.

6.How can customization options be integrated into the stuffed animal production process?

Customization adds unique features like logos, colors, or accessories, meeting client needs and enhancing product appeal.

Customization involves design variations, embroidery, printing, and accessory attachment, integrated into pattern and production stages.

Customization starts during design, adjusting patterns for unique shapes or features. Embroidery and printing allow logos or messages on fabric.

Accessory attachment includes ribbons, clothing, or sound modules, added before final stitching. This requires coordination between design, production, and QC teams to maintain quality.

Custom colors or materials may extend lead times and require additional testing. However, they offer brand differentiation and higher value for clients.

| Customization Type | Integration Stage | Benefits |

|---|---|---|

| Embroidery | Pattern and sewing | Brand logos, personalization |

| Printing | Fabric preparation | Colorful designs, branding |

| Accessories | Final assembly | Added play value, uniqueness |

Custom options help suppliers like Kinwin meet diverse client demands and market trends.

Conclusion

Producing quality stuffed animals requires careful material selection, skilled design, precise stitching, rigorous quality control, and flexible customization.

For expert plush toy manufacturing and customization, contact Amanda at [[email protected]] or visit [https://plushtoyinchina.com].