Custom Plush Toy Manufacturer in China

Discover why top global brands trust our Chinese factory for premium custom plush toys, hassle-free.

You gain CE & ASTM-certified safety, fully customizable designs, competitive pricing, on-time delivery, and exceptional durability from our 17-year China factory—ensuring your brand stands out with reliable, high-quality plush toys.

Discover Our Competitive Manufacturing Advantages

For over 17 years, Kinwin’s Dongguan factory has helped brands turn plush toy ideas into high-quality, best-selling products.

- Our factory is equipped with German automated stitching lines and Japanese filling systems, supporting an annual output of over 10 million units—while maintaining strict precision and quality.

- All plush toys meet CE and ASTM standards, with a 6-step QC system including raw material checks, colorfastness testing, in-line stitch audits, and tensile strength verification.

- We offer transparent pricing with no hidden costs. Enjoy low MOQs starting at just 200 units and lean production for cost-effective sourcing.

- Get samples in as fast as 5 days to test market trends quickly. Once approved, bulk orders are ready to ship within 15–30 days—keeping your inventory flexible.

- Work with a project manager who oversees your custom order from design consultation to final shipping. From embroidery to fabric matching to eco-packaging, we deliver tailored solutions.

- We ship your branded plush toys efficiently to the USA, Europe, Japan, South Korea, and the Middle East—with full logistics support to ensure on-time arrival.

- Choosing Kinwin means gaining a reliable OEM & ODM partner focused on helping your brand grow—through better quality, faster time-to-market, and stronger profits.

Explore Our Diverse Plush Toy Collections

Your brand needs diverse plush toys for retail success. Kinwin offers unique designs, driving global market impact.

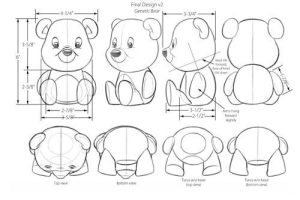

Teddy Bear Plush Toy

Cartoon Character Dolls

Lifelike animal plush toys

Food Themed Plush Toys

Cute expression plush toy

Alphanumeric plush pillow

Plush Cushion Pillow

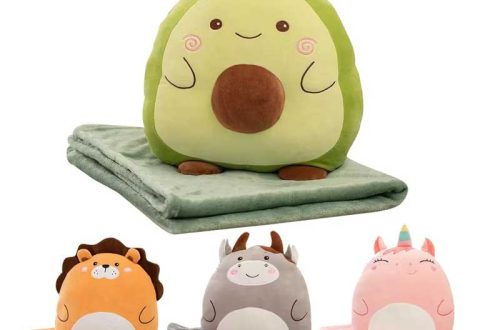

Blanket and plush toy set

Backpack Plush Toy Set

Keychain Plush Ornaments

Oversized plush pillow

Interactive sound plush toy

Musical dynamic plush toy

Sensory Fidget Plush Toys

Luminous plush toys

Eco-Friendly Material Plush

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Learn About Our Company’s Core Values

Quality Comes First

Customer-Focused Service Model

Innovation-Driven Product Design

Sustainability and Responsibility

Fabrics & Texture Options

At Kinwin, we offer over ten premium plush fabrics—Coral Fleece, Minky, Faux Fur, Velboa, and more—balancing softness, durability, and safety. Fully customizable in texture, color, and pile height, our materials ensure your designs meet diverse aesthetic and functional requirements, elevating your product line.

Minky Plush

Our Minky fur offers ultra-soft texture with excellent resilience, perfect for high-end luxury plush toys.

Polyester Plush

Durable polyester plush withstands extensive playtime while maintaining shape, colorfastness, and easy care for customers.

Faux fur

Faux fur options mimic real animal fur, offering plush appeal, hypoallergenic properties, and eye-catching textures.

Cotton blend fabrics

Cotton blend fabrics provide breathable comfort, natural feel, machine-washable convenience, and eco-friendly appeal for brands.

High-pile plush

High-pile plush adds luxurious depth, vibrant look, and tactile richness, ideal for premium character designs.

Velboa

Velboa fabric offers short-pile softness, smooth finish, bright colors, durability, and easy customization for designs.

stain-resistant fabrics

Special stain-resistant fabrics maintain overall clean appearance, simplify maintenance, and extend plush toy lifespan significantly.

Recycled fiber

Recycled fiber fabrics offer sustainable sourcing, impressive durability, and alignment with eco-conscious global consumer values.

Textured Jacquard patterns

Textured Jacquard patterns introduce texture, depth, and unique aesthetics, elevating plush designs with intricate woven details.

Chenille fabrics

Chenille fabrics deliver soft velvet-like feel, excellent color vibrancy, and durability for engaging tactile experiences.

Select High-Quality Filling Materials Easily

Polyester Hollow Fiber

Our microfiber polyester hollow fiber comes in three tiers:

- Siliconized Grade A: Exceptionally resilient, maintains loft and bounce—ideal for high-end cuddly plush dolls.

- Standard Grade B: Cost-effective with good support and softness—perfect for mass-market teddy bears and cushions.

- Micro-Denier Grade C: Ultra-fine filaments for an exceptionally silky hand feel—used in luxury baby blankets and premium character plushies.

Each grade balances cost, resilience, and softness differently. You choose Grade A for superior shape retention, Grade B for everyday volume, or Grade C when ultra-soft touch is critical. Common applications include stuffed animals, pillow hybrids, and sensory toys.

EPP Bead Filling

Expanded polypropylene (EPP) beads are available in:

- Standard Bead: Lightweight, durable, and moisture-resistant—used in beanbag-style plush chairs.

- Round Premium Bead: Smoother feel and quieter movement—preferred for weighted sensory animals.

- Bead-Fiber Blend: Adds structure with softness—great for decorative plush cushions and novelty toys.

EPP beads provide moldable support without compaction over time. You can opt for pure beads for malleability, premium beads for a hush-quiet feel, or blends for shape and softness. Common in beanbag toys, floor pillows, and therapy plush.

Bean Pellet Filling

Our food-grade pellets come in four categories:

- Smooth PVC Pellets: Economical, smooth texture—widely used in collectible figurine plushies.

- Textured PE Pellets: Improved grip and weight—ideal for floor-sitting animals.

- Recycled Eco-Pellets: Sustainable option made from post-consumer plastics—appeals to green-focused clients.

- Natural Glass Beads: Premium weight and stability—used in luxury weighted lap pads and specialty dolls.

Pellet grades differ in weight, texture, and sustainability profile. You choose PVC for budget lines, PE for tactile grip, recycled pellets for eco credentials, or glass beads for premium heft. Typical uses include keychain toys, weighted comforters, and poseable plush figures.

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Review Detailed Product Specifications & Dimensions

Mini Keychain Plush

Dimensions: 8 cm (3.15″ )

Ideal for promotional giveaways and handbag accents.

Small Handheld Plush

Dimensions: 15 cm (5.91″)

Perfect for pocket-sized toys and child-friendly grips.

Standard Collectible Plush

Dimensions: 25 cm (9.84″)

Best for collectible lines and retail displays.

Medium Hug-Me Plush

Dimensions: 35 cm (13.78″)

Designed for comfortable cuddling by children.

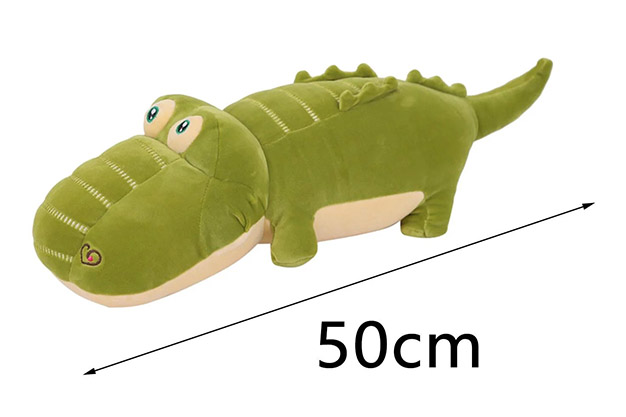

Large Floor-Sitter Plush

Dimensions: 50 cm(19.69″)

Suited for room décor and floor play.

Oversized Pillow Plush

Dimensions: 70 cm (27.56″)

Makes a statement piece for nurseries and lounges.

See How Our Plush Production Process Works

Discover our streamlined, end-to-end plush manufacturing workflow in China—from concept and prototyping through stitching, filling, inspection, and packaging—to deliver custom plush toys that exceed quality and safety expectations every time.

1-Initial concept and design

2-Rapid prototyping

3-Material procurement

4-Pattern making and cutting

5-Professional sewing

6-Filling material

7-Quality Inspection

8-Brand Label

9-Package

10-Shipping

Customize Your Logo with Tags, Embroidery or Print

Leverage versatile logo customization options—woven labels, detailed embroidery, and precision printing—to reinforce brand identity, enhance product aesthetics, ensure durability, meet compliance, create memorable plush toys that resonate with your audience.

Embroidery

Woven Label

Screen Printing

Silicone Patch

Hang Tag

Metal Badge

Heat Transfer

PU Transfer

Protect Your Brand with Custom Packaging Solutions

Branded Printed Gift Boxes

Eco-Friendly Kraft Mailers

Custom Polybag Inserts

Luxury Drawstring Velvet Bags

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Ensure Quality with Rigorous Inspection Protocols

From raw materials to final shipment, every step is verified for consistent excellence.

Incoming Raw Material Inspection

Block quality issues before production begins.

- Every batch of fabric, filling, and accessories is checked against your exact specifications.

- QA team tests color accuracy, fiber composition, weight, and texture.

- Certifications such as OEKO-TEX and REACH are verified for compliance.

- Colorfastness and surface finish tests are conducted on samples before approval.

- Early detection reduces waste, avoids rework, and ensures high product safety from day one.

In-Process Stitch Integrity Review

Maintain durability and precision at every workstation.

- Spot checks are conducted on seam strength, stitch density, and thread tension.

- Loose threads, skipped stitches, or misalignments are identified and corrected immediately.

- Gauges and tensile testers are used to ensure every seam meets strength standards.

- Embedded checks prevent large-scale issues and downtime.

- Build quality remains consistent across high-volume production.

Mid-Run Sample Audits

Catch deviations before they affect the whole batch.

- Random samples are pulled mid-production to compare with approved prototypes.

- Dimensional accuracy, fill density, and surface texture are carefully evaluated.

- Fabric color and saturation are assessed for consistency.

- Any quality drift triggers immediate analysis and corrective action.

- Prevents batch-to-batch variability and ensures brand standards are met.

Final Cosmetic & Safety Assessment

Every unit is inspected before it reaches your customer.

- Each toy is reviewed for visual defects like loose fibers, dye spots, or crooked features.

- Safety checks cover odor, choking risks, and secure attachment of small parts.

- Mechanical stress simulations are performed on buttons, zippers, and embellishments.

- Every plush toy must pass CE and ASTM safety benchmarks.

- Final inspections minimize customer complaints and product returns.

Third-Party Lab Certification Testing

Independent validation that earns global trust.

- Accredited labs test for flammability, heavy metals, phthalates, and mechanical safety.

- Reports verify compliance with global toy safety standards (CE, ASTM, EN71, etc.

- Documents are suitable for retailers, regulators, and customs clearance.

- Adds credibility and builds buyer trust in international markets.

- Positions your brand as a responsible, certified plush toy manufacturer

Stay Ahead with 2025 Plush Toy Trends

Catch the wave—6 big trends shaping the future of plush toys

Eco-Friendly Fabrics Are the New Standard

Recycled, Responsible, Remarkable

Smart Plush Is Smarter Than Ever

Touch, Talk, Teach—Tech That Hugs Back

Nostalgia Is a Goldmine

Retro Looks. Modern Quality. Timeless Charm.

Customization Gets Personal

From Factory Line to One-of-a-Kind

Wellness & Sensory Toys Are Booming

Comfort Meets Care

Vinyl Collectibles Join the Party

More Than Plush—Build a Pop Culture Brand

All Your Questions, Answered in One Place (FAQ)

We understand: ordering customized plush toys from overseas isn’t a small decision. That’s why we’ve answered your most common questions here—to save you time, reduce back-and-forth, and help you move forward with confidence.

1. What’s your minimum order quantity?

You can start with as few as 200 pieces per design, enabling low-risk sampling before committing to larger bulk orders.

2. How long is the sample lead time?

You receive prototype samples within 10-15 days after design approval, so you can evaluate quality and fit market needs quickly.

3. What’s the bulk production lead time?

Bulk orders ship in 15–30 days post-sample approval, depending on order size and customization complexity, keeping your launch schedule on track.

4. Which payment terms do you offer?

You benefit from flexible terms: 30% deposit upfront and 70% balance before shipment, with T/T, L/C, PayPal, or Alibaba Trade Assurance.

5. What customization services are available?

You choose from custom logos, embroidery, multi-fabric mixing, sound modules, and eco-friendly packaging—fully tailored to your brand’s specifications.

6. Do your products meet safety standards?

You gain confidence knowing all plush toys comply with CE, ASTM, and EN71 certifications, validated through both in-house and third-party lab tests.

7. What packaging options can I select?

You pick from printed gift boxes, eco mailers, polybag wraps, velvet pouches, or corrugated shippers—each branded to enhance unboxing experiences.

8. Which shipping methods are supported?

You optimize logistics with sea freight, air express, door-to-door courier, rail transport, or DDP service, matching cost, speed, and convenience.

9. How do you ensure product quality?

You benefit from six-stage inspections—raw material checks, in-process audits, mid-run sampling, final cosmetic assessments, and third-party certification testing.

10. How can I start my order?

You simply email [email protected] or submit our online form. A dedicated project manager will guide you step by step.

Still Have Questions?

We’re just one message away. Contact us and let’s build your next plush toy bestseller—together.

If You Can lmagine lt,We Will Create lt!

1.Tell Us What You Need

Tell us as specific as possible of your needs and share your idea.

2.Get Solution & Quote

We will work on the best solution according to yourrequirements,the specific quote will be provided within 24 hours.

3.Approve for Mass Production

We will start mass production after getting your approval.