Your Trusted Custom Plush Toy Manufacturer

From Design to Delivery, We’re Not Just Manufacturers—We’re Your Brand Co-Creators.

Every Plush Toy, A New Story Begins.

Plush Toy Supplier for Global Retailers with Competitive Prices

Welcome to the premier destination for customized plush toys—your trusted custom plush toy manufacturer. At KINWIN, we specialize in transforming your ideas into reality with personalized plush toys that reflect your unique vision and meet practical needs. Whether you’re a toy retailer, wholesaler,importer, gift shop, or design firm, our factory is equipped to craft plush toys that blend creativity, safety, and appeal seamlessly.

Tailored to Your Vision

Imagine a plush toy designed to your exact specifications:

- Design: From classic stuffed animals to unique custom figures.

- Color: Vibrant or subtle, matching your brand’s identity.

- Size: Perfectly scaled for your target market.

- Packaging: Customized to enhance your product’s presentation.

Each toy is meticulously crafted by skilled artisans who prioritize quality and safety, using soft, safe materials that delight customers and meet industry standards. Our customization options ensure your plush toys not only meet but exceed your expectations.

Elevate Your Brand

At KINWIN, we understand the needs of B2B clients. Our plush toys offer:

- Soft, safe materials: Ideal for all ages, ensuring customer satisfaction.

- Customizable options: Tailor every detail to align with your brand and market demands.

Whether you’re stocking shelves, fulfilling wholesale orders, or creating exclusive designs, we’re here to help you stand out with premium personalized plush toys.

Our Products

With years of experience in the plush toy industry, Kinwin offers the following core product categories for B2B customers, each fully customizable to your brand requirements:

Classic Plush Toy Series

Stuffed Animal Series

Custom Plush Figures

Smart Tech Plush Toys

Themed Mascots & IP Merchandise

Gifts & Promotional Giveaways Series

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Why Choose a Professional Plush Toy Manufacturer?

1.Deep Industry Expertise

15 advanced production lines with annual output in the tens of millions

Years of focus on plush toys, well-versed in global markets and regulations

2.Rigorous Quality & Safety Control

End-to-end QC in-house, compliant with ASTM F963, CE, EN71

Third-party lab testing to guarantee batch-to-batch consistency

3.Flexible OEM & ODM Customization

Full-cycle service from concept design to finished product

Embroidery, printing, color matching, and tech modules (GPS, sound chips)

4.Cost & Efficiency Optimization

Factory-direct supply cuts out middlemen to lower costs

Standardized workflows and scale production shorten lead times

5.Comprehensive Certifications & Credentials

ISO 9001 QMS certified

Registered toy products and compliance in eco-friendly material sourcing

6.Efficient & Reliable Global Logistics

Partnerships with leading global shippers for on-time delivery

One-stop customs clearance support minimizes risk and expense.

7.Dedicated Customer Service & Technical Support

24/7 multilingual support team for rapid response

Complimentary samples, regular project follow-ups, and after-sales care

Advantages of Partnering with Us

1

One-Stop Customization

From concept design and prototyping to mass production, we offer an end-to-end one-stop solution that streamlines your procurement.

2

Scalable Production Capacity

With 15 advanced production lines, we flexibly scale capacity to meet both bulk orders and seasonal peaks.

4

Rigorous Quality Control

We adhere to ASTM F963, CE, EN71 and other international standards, with third-party testing to guarantee consistent, high-quality output.

5

Cost-Competitive Pricing

Our factory-direct model eliminates intermediaries, leveraging economies of scale to offer you highly competitive pricing.

6

Fast Turnaround & Flexible Lead Times

Standardized workflows and priority scheduling ensure on-time delivery for critical projects, helping you seize market windows.

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

we’ve produced over 50000 unique plushies

At Kinwin, we pride ourselves on crafting over 50,000 unique plush toy designs that delight global partners. Our diverse portfolio spans classic characters, custom mascots, and intelligent interactive toys. Working with renowned retailers, gift shops, and tech brands, we deliver innovation, quality, and bespoke service for every project and partnership worldwide.

Fabrics & Texture Options

At Kinwin, we offer over ten premium plush fabrics—Coral Fleece, Minky, Faux Fur, Velboa, and more—balancing softness, durability, and safety. Fully customizable in texture, color, and pile height, our materials ensure your designs meet diverse aesthetic and functional requirements, elevating your product line.

Coral Fleece

Composition: 100% polyester

Features: Ultra-fine fibers, smooth touch, lightweight yet warm, excellent dyeing and printing properties.

Applications: Ideal for keychain plush, pillow covers, toy clothing.

Minky Plush

Composition: 100% microfiber polyester

Features: Available in dot or solid styles, plush and elastic, luxurious feel.

Applications: Perfect for baby toys, blankets, premium collectible plush.

Velboa

Composition: Polyester blend

Features: 0.5–3mm short pile, smooth, durable, easy care, cost-effective.

Composition: Suited for mass-produced classic toys and character plushies.

Faux Fur

Composition: PU backing + polyester pile

Features: Pile up to 20mm, realistic fur look, premium luxury feel.

Applications: Perfect for luxury teddy bears, theme mascots, movie/TV merchandise.

Polar Fleece

Composition: 100% polyester or poly-cotton blend

Features: Double-faced pile, excellent warmth, thick hand feel.

Applications: Ideal for winter-themed plushies and holiday mascots.

Sherpa Fleece

Composition: 100% polyester

Features: Curly sherpa look, fluffy, moisture-wicking, natural 3D texture.

Applications: Used in winter gift sets and storybook companion toys.

Microfiber Plush

Composition: Ultra-fine polyester microfiber

Features: Dense, durable, anti-pilling, glossy finish.

Applications: Suitable for frequently handled toys, easy maintenance.

Cotton

Composition: 100% cotton

Features: Natural, eco-friendly, breathable, soft to the touch.

Applications: Best for baby lines and safety education toys..

Knit Plush

Composition: Poly-cotton or nylon blend

Features: High elasticity, smooth surface, ideal for complex shapes.

Applications: Used for intricately shaped character dolls.

Woven Plush

Composition: Polyester or poly-cotton blend

Features: High dimensional stability, stretch-resistant, abrasion-resistant.

Applications: Ideal for large pillows and structural plush components.

Jacquard Plush

Composition: Polyester

Features: Rich jacquard patterns, strong relief effect.

Applications: Perfect for holiday themes and patterned custom dolls.

Velvet

Composition: 100% polyester or polyester-cotton blend

Features: Luxuriously soft, smooth touch, subtle sheen for a premium look.

Applications: Ideal for premium collectible dolls and gift sets.

Terry Plush

Composition: 100% polyester with looped pile

Features: Looped texture for durability, breathability, and 3D effect.

Applications: Perfect for baby lines and educational plush toys.

Embroidered Plush

Composition: Base fabric (Minky/Velboa) + embroidery threads

Features: Combines plush base with detailed embroidery, highly durable.

Applications: Great for logo customization and limited-edition collectibles.

The Art of Plush Toy Stuffing · Crafting the Perfect Feel

Kinwin offers a variety of premium stuffing materials to meet diverse tactile, safety, and functional requirements. Below is a comprehensive list of common plush toy filling options:

Polyester Fiberfill

Composition:100% polyester staple fiber

Features:High resilience, quick loft recovery, resists clumping, machine washable.

Natural Cotton

Composition:100% natural cotton

Features:Eco-friendly, breathable, skin-friendly—ideal for baby lines.

Polypropylene Cotton

Composition:polypropylene fiber

Features:Lightweight, antibacterial, moisture-resistant, cost-effective.

Recycled Polyester Fiberfill

Composition:100% recycled polyester fiber

Features:Eco-friendly, low carbon footprint, performance on par with virgin polyester.

Microbeads

Composition: polystyrene or silica microbeads

Features:Fine tactile feel, highly moldable—perfect for realistic shapes.

Expanded Polystyrene Beads

Composition:expanded polystyrene microbeads

Features:Ultra-light, excellent shape retention, high support—ideal for bean bag toys.

Silica Gel Beads

Composition:food-grade silica gel beads

Features:Moderate weight, moisture-resistant, adds a weighted feel.

Foam Sponge

Composition:polyurethane foam

Features:Cut-to-shape, porous for shock absorption, used for structural support.

Memory Foam Pellets

Composition:polyurethane memory foam fragments

Features:High rebound, conforms to touch, provides a luxury feel.

Bamboo Fiber

Composition:regenerated bamboo pulp fiber

Features:Naturally antibacterial, quick-drying, breathable—ideal for eco ranges.

Wool

Composition:natural wool

Features:Excellent warmth, biodegradable—used in premium custom pieces.

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Logo Implementation Methods

Kinwin offers a range of professional logo application techniques to enhance brand recognition and value.

Embroidery

Description:Multicolor threads stitched for durability and 3D effect.

Suitable For:Plush toy bodies, clothing

MOQ:500

Woven Label

Description:High-density woven labels, sew-on or heat-seal, fade-resistant.

Suitable For:Fabric labels, neck tags

MOQ:500

Heat Transfer

Description:Heat-press transfers for complex colors & gradients.

Suitable For:T-shirt style panels

MOQ:300

Screen Printing

Description:Durable flat layer printing for high-volume runs.

Suitable For:Flat fabric areas, pillow backs

MOQ:500

Silicone Patch

Description:Eco-friendly silicone molded patches, waterproof and scratch-resistant.

Suitable For:Toy soles, backpack charmss

MOQ:200

PU Transfer

Description:Laser-cut PU film transfers, thin and flexible.

Suitable For:Toy masks, decorative panels

MOQ:500

Laser Engraving

Description:Laser-etched marking on PU or leather, precise and long-lasting.

Suitable For:Premium gift boxes, metal badges

MOQ:100

Hang Tag

Description:Double-sided paper or plastic tags to enhance unboxing.

Suitable For:All finished product packaging

MOQ:500

Packaging Print

Description:Logo printing on boxes, bags, or cards, shipped with product.

Suitable For:Gift boxes, bags, hang cards

MOQ:500

Metal Badge

Description:Die-cast aluminum or zinc badges with plating for a premium look.

Suitable For:Premium plush badges

MOQ:500

Artisan Craftsmanship · Handcrafted Details Meets Modern Mastery

At Kinwin, we blend time-honored handcraft techniques with modern manufacturing to ensure every plush toy reflects superior artistry and meticulous detail.

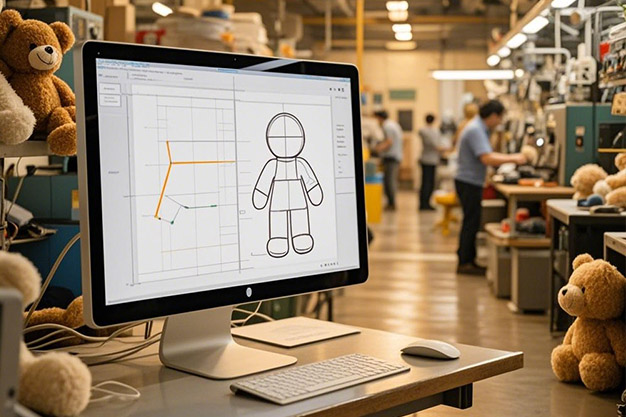

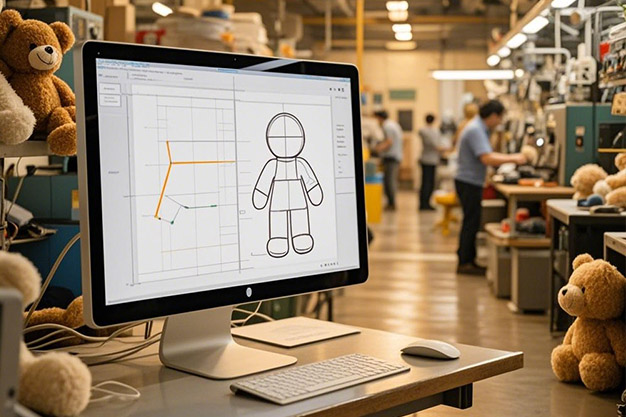

Precision Pattern & Prototyping

Utilizing CAD design and hand-cut patterns to guarantee flawless proportions.

Premium Fabric Cutting

Combining laser precision and manual cutting to minimize fraying and enhance finish.

Hand-Stitched Detailing

Key areas (ears, paw pads, decorative accents) hand-stitched by skilled artisans using backstitch for tight, durable seams.

Overlock & Buttonhole Stitching

Overlocked edges prevent unraveling, while buttonholes and attachments are securely stitched for safety and aesthetics.

Filling & Shaping

Sectional stuffing with hand-molding ensures plush fullness and consistent softness.

Detailed Embroidery & Embellishments

Multicolor embroidery for facial features and patterns; sequins and embellishments applied individually by hand.

Rigorous Hand Inspection & Pressing

Every toy undergoes stitch-by-stitch hand inspection by QC and steam pressing to achieve flawless presentation.

Final Quality Check & Packaging

Post-assembly checks for color fastness, seam strength, and filling consistency; shipped in bespoke packaging upon approval.

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Diverse Plush Toy Collections · Explore Infinite Creativity & Customization

Kinwin’s expansive plush toy collections feature over ten innovative lines, including classic teddy bears, animal characters, plant & fruit designs, baby series, keychains, home & lifestyle plush, handbag dolls, holiday-themed toys, pet-safe models, and electrified plush. We offer full customization and functional integrations, ensuring tear-resistance, superior resilience, and easy cleaning. Whether for seasonal gifts or everyday décor, Kinwin provides high-quality, factory-direct solutions with bulk discounts to meet your brand’s diverse needs.

Classic Teddy Bear

- Key Features:Iconic round-face & ears

- Fabrics:Minky, Coral Fleece, Velboa

- Fillings:Fiberfill, Memory Foam

- Use Cases:Gift shop keepsakes,Nursery décor

- Customization & Value-Adds:LogoEmbroidered names/logos,Custom gift-box

- Production & Lead Time:MOQ 200;Samples 7–10d;Bulk 25–30d

Animal Plush

- Key Features: Realistic shapes, poseable joints

- Fabrics: Faux Fur, Velboa, Microfiber

- Fillings: Polypropylene, EPS beads

- Use Cases: Theme-park merchandise, Zoo souvenirs

- Customization & Value-Adds: Gradient & two-tone fabrics, Detachable accessories

- Production & Lead Time: MOQ 300; Samples 10–12d; Bulk 30–35d

Plant & Fruit Plush

- Key Features: Vibrant colors, cartoon shapes

- Fabrics: Coral Fleece, Velboa, Embroidered

- Fillings: Fiberfill, Silica beads

- Use Cases: Restaurant décor, Health-food giveaways

- Customization & Value-Adds: Printed slogans, Limited-edition numbering

- Production & Lead Time: MOQ 250; Samples 7–9d; Bulk 20–25d

Baby Plush

- Key Features: Formaldehyde-free, hypoallergen

- Fabrics: Cotton, Minky, Sherpa

- Fillings: Polypropylene, Recycled fiber

- Use Cases: Baby-shower gifts, Soothing toys

- Customization & Value-Adds: Embroidered baby names, Custom safety tags

- Production & Lead Time: MOQ 150; Samples 5–7d; Bulk 18–22d

Keychain Plush

- Key Features: Mini size (5–12 cm)

- Fabrics: Velboa, Coral Fleece, Embroidered

- Fillings: Fiberfill, EPS beads

- Use Cases: Promotional giveaways, Merchandise sales

- Customization & Value-Adds: Personalized beads/charms, Low MOQ support

- Production & Lead Time: MOQ 500; Samples 4–6d; Bulk 12–15d

Home & Lifestyle Plush

- Key Features: Multi-functional (pillows, slippers)

- Fabrics: Coral Fleece, Polar Fleece, Faux Fur

- Fillings: EPS beads, Foam sponge

- Use Cases: Home décor, Mall/hotel gifts

- Customization & Value-Adds: Large prints/embroidery, Removable covers

- Production & Lead Time: MOQ 100; Samples 10–12d; Bulk 25–28d

Handbag Dolls

- Key Features: Built-in chains/clips

- Fabrics: Velvet, Faux Fur, Embroidered

- Fillings: Memory foam, Fiberfill

- Use Cases: Fashion accessories, E-commerce gifts

- Customization & Value-Adds: Custom hardware, Personalized tags

- Production & Lead Time: MOQ 200; Samples 8–10d; Bulk 22–26d

Holiday & Seasonal Plush

- Key Features: Holiday motifs, limited editions

- Fabrics: Jacquard, Sherpa, Coral Fleece

- Fillings: Fiberfill, Recycled fiber

- Use Cases: Mall displays, Corporate gifts

- Customization & Value-Adds: Themed colorways & prints, Limited numbering

- Production & Lead Time: MOQ 300; Samples 7–9d; Bulk 18–22d

Pet-Friendly Plush

- Key Features: Tear-resistant, waterproof, no loose fibers

- Fabrics: TPU coated, Knit plush, Faux Fur

- Fillings: High-density fiberfill, Silica beads

- Use Cases: Pet chew toys, Pet comfort cushions

- Customization & Value-Adds: Engraved/embroidered pet names, Chew-ring attachments

- Production & Lead Time: MOQ 250; Samples 10–12d; Bulk 28–32d

Electrified Plush Toys

- Key Features: Built-in chips, LEDs, GPS

- Fabrics: Velvet, Microfiber, Embroidered

- Fillings: Memory foam, Silica beads

- Use Cases: Educational & comfort toys, Smart home toys

- Customization & Value-Adds: App connectivity, Swappable modules

- Production & Lead Time: MOQ 150; Samples 12–15d; Bulk 35–40d

Plush Toy Manufacturing Process

Kinwin plush toy manufacturing process spans requirement alignment, concept design, prototyping, material verification, cutting, sewing, stuffing, craft embellishment, quality inspection, steaming & shaping, and packaging & shipping. With rigorous controls and traceability at every stage, we ensure safety compliance, quality excellence, and on-time delivery, delivering an efficient, dependable, and fully customized production experience.

1.Requirement Gathering & Concept Design

Through collaborative discussions, we clarify product positioning, functionality, budget constraints, and branding goals. Our design team develops detailed sketches, 3D renderings, and technical drawings to visualize concepts accurately and efficiently.

- Align on product positioning, functional requirements, and budget.

- Design team produces sketches, 3D renders, and technical drawings.

2.Pattern Making & Prototyping

We generate precise CAD patterns, refine them manually for flawless fit, then produce initial prototypes. Clients review and request revisions, ensuring sample iterations meet design intent, functional requirements, and quality expectations before final approval.

- Generate precise patterns via CAD and refine them manually.

- Create initial prototype for client review and iterations.

3.Material Sourcing & Preparation

After prototype confirmation, we finalize the bill of materials listing fabrics, fillings, trims, and electronics. All raw materials undergo rigorous quality inspections and certification audits to verify safety, sustainability, and compliance standards.

- Finalize BOM of fabrics, fillings, and accessories.

- Inspect raw materials and verify environmental and safety certifications.

4.Fabric Cutting

Large fabric panels are laser-cut or die-cut for speed and precision, while artisans hand-cut intricate sections. Each piece is marked, bundled, and organized systematically to optimize workflow efficiency and minimize material waste.

- Laser or die-cut large pieces; hand-cut detailed sections.

- Mark and sort cut pieces for streamlined assembly.

5.Main Component Sewing

Industrial sewing machines stitch main body components with reinforced seams for durability. Skilled craftsmen hand-reinforce critical areas like ears and paw pads using specialized backstitch techniques, ensuring long-lasting structural integrity and detail fidelity.

- Use industrial sewing machines for main body seams for durability.

- Artisans hand-reinforce key details (ears, paw pads).

6.Assembly & Stuffing

We perform zonal stuffing with polyester fiber or specialty materials, manually shaping contours. For electrified toys, technicians install sound chips, LEDs, and GPS modules. This integrated approach ensures both form and function.

- Stuff zones with polyester fill or specialty materials; hand‐shape contours.

- Install sound chips, LEDs, GPS modules where required.

7.Craft Embellishments

Expert artisans apply embroidery, heat transfers, screen prints, and patches. Small accessories such as button eyes, charms, and appliqués are hand-attached with precision, enhancing visual appeal and delivering bespoke decorative flourishes.

- Apply embroidery, heat transfers, and patches.

- Hand-attach small accessories (button eyes, charms).

8.Quality Inspection

In-line spot checks monitor dimensions, seam strength, and fill consistency during production. Finished items undergo comprehensive UDI testing for ASTM F963, CE, and EN71 compliance, plus functional tests to guarantee safety and performance.

- In-line spot checks for dimensions, seam strength, and fill consistency.

- Final UDI tests for safety compliance (ASTM/CE/EN71) and functionality.

9.Steam Pressing & Final Shaping

Products are steam-pressed to remove fabric wrinkles, sharpen silhouettes, and finalize surface appearance. This critical finishing step ensures each toy exhibits a polished, professional look and consistent presentation across all units.

- Steam-press to remove wrinkles and finalize surface presentation.

10.Packaging & Shipping

Custom packaging solutions—gift boxes, hang cards, vacuum pouches—are assembled per specifications. Each package is labeled, tracked, and accompanied by customs documentation. We coordinate logistics, ensuring safe, on-time global delivery and support.

- Pack in gift boxes, hang cards, or vacuum pouches per spec, and label.

- Offer shipment tracking and customs support for timely delivery.

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Comprehensive Quality Inspection System

Kinwin has implemented a rigorous, multistage quality inspection system covering incoming material checks, in-line spot checks, functional testing, safety compliance testing, final inspection, packaging audit, batch traceability, and after-sales monitoring. Partnering with third-party laboratories, we ensure every batch meets ASTM F963, CE, EN71, and other international standards. Our end-to-end traceability and rapid feedback loop guarantee worry-free quality assurance for our customers.

1.Incoming Material Inspection

2.In-Line Process Spot Checks

3.Functional Module Testing

4. Safety Compliance Testing

5.Final Inspection

6.Packaging Quality Audit

7.Batch Traceability

8.After-Sales Monitoring

Future Trends in Plush Toys

As technology advances and consumer expectations evolve, the plush toy industry is entering a new era of smart, sustainable, and personalized products. Internet of Things (IoT) and AI technologies are being integrated into toys to deliver interactive play and educational benefits. Meanwhile, heightened environmental awareness drives the adoption of biodegradable and recycled materials, aligning brands and consumers with sustainable practices. Additionally, digital platforms and on-demand manufacturing empower bespoke customization, satisfying the desire for one-of-a-kind creations. Going forward, manufacturers must balance technological innovation, green supply chains, and agile production to enhance both brand differentiation and market competitiveness. Cross-industry collaborations, IP licensing, and omnichannel marketing will further reshape the landscape, unlocking added-value opportunities for B2B and B2C customers worldwide.

Smart Connectivity & Interactive Play

With built-in sensors, voice recognition, and AI, plush toys will evolve into smart companions offering emotional interaction, learning support, and remote monitoring capabilities.

Sustainable Materials & Circular Economy

Bio-based fibers, recycled polyester, and biodegradable stuffing will dominate, complemented by reusable packaging to create an eco-friendly closed-loop from raw materials to end-of-life.

Digital Customization & On-Demand Manufacturing

Leveraging online 3D configurators and rapid small-batch prototyping, brands can offer limited-edition, personalized plushies for various markets, minimizing inventory and swiftly responding to trends.

Green Production

Kinwin upholds green production principles across the entire manufacturing process—from energy management and wastewater treatment to emission monitoring—minimizing its carbon footprint. We harness solar power and energy-efficient lighting to reduce electricity use; install centralized cooling and waste‐heat recovery systems for energy reuse; and deploy smart monitoring to track equipment energy and emissions in real time, enabling continuous process optimization. Workshop effluent undergoes tertiary biotreatment, while solid waste is sorted for maximum recycling. We use eco‐friendly water-based adhesives instead of traditional solvent‐based glues to cut VOC emissions. These initiatives have achieved over 20% energy savings and a 30% waste recycling rate, delivering more sustainable plush toy solutions to our global clients.

Eco-Friendly Raw Materials

promoting a sustainable supply chain. We prioritize purchasing recycled polyester certified by Oeko-Tex®, GRS, and FSC®, along with non‐toxic dyes and natural cotton. Partnering with certified suppliers, we ensure traceable sources free of heavy metals, plasticizers, or allergens. For fillings, we increasingly adopt biodegradable and plant‐based fibers such as PLA (polylactic acid) to reduce plastic micro‐pollution. For specialized functions, we choose food‐grade silica beads and recyclable EPS beads, balancing safety with circularity. All raw materials undergo third‐party testing upon arrival to verify compliance with REACH, RoHS, and ASTM standards, offering clients risk-free, high-quality eco‐friendly options.

If You Can lmagine lt,We Will Create lt!

1.Tell Us What You Need

Tell us as specific as possible of your needs and share your idea.

2.Get Solution & Quote

We will work on the best solution according to yourrequirements,the specific quote will be provided within 24 hours.

3.Approve for Mass Production

We will start mass production after getting your approval.