Custom Plush Maker in China

Partner with China’s leading custom plush manufacturer for seamless OEM/ODM services and global brand support

You receive fully tailored plush designs, CE and ASTM certified safety, competitive pricing, fast turnaround, and dedicated support, so you can exceed customer expectations and boost retail or promotional success.

Meet Our Seasoned Manufacturing Team

Plush Toy Manufacturing That’s Built for Brands

With over 17 years of experience, Kinwin is a modern plush toy factory trusted by top retailers, toy brands, and licensing partners worldwide.

Our 20,000 m² facility in Dongguan, China, is equipped with German sewing lines, Japanese stuffing systems, and an in-house testing lab—allowing us to manage every step of production under one roof:

17+ years

- Concept design & rapid prototyping

- Certified production (CE, ASTM, EN71)

- Quality inspection & compliance control

- Flexible logistics, including DDP and global delivery

We support low MOQs, transparent pricing, and agile OEM/ODM services—perfect for growing brands or licensed collections.

From the first sketch to final shipment, Kinwin brings your plush idea to life with speed, care, and factory-direct confidence.

Explore Our Full Range of Custom Plush Products

Your brand needs diverse plush toys for retail success. Kinwin offers unique designs, driving global market impact.

Classic Teddy Bear Collection

Licensed Character Plush Toys

Educational Learning Plush Toys

Sensory & Therapeutic Plush

Pet-Safe Chew-Resistant Plush

Seasonal & Holiday Plush Editions

Oversized Lounge & Decor Plush

Interactive Electronic Plush

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

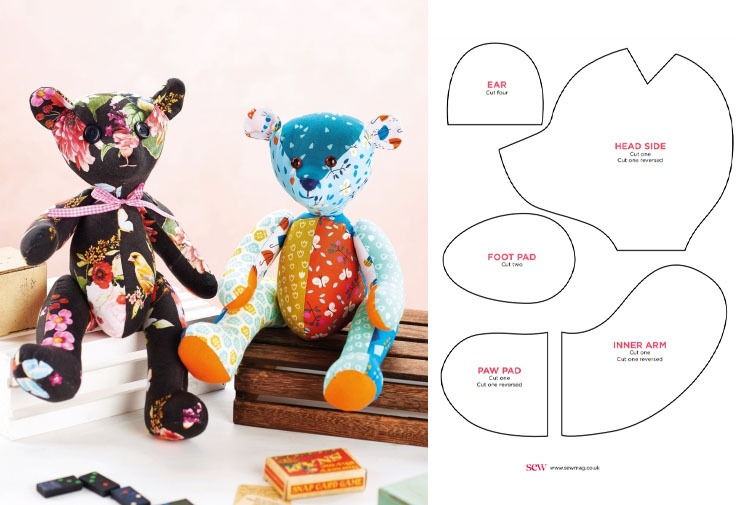

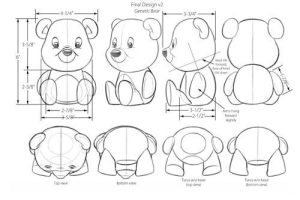

Design Innovative Plush Structures for Durability

Integrated Support Framework

Internal mesh and molded foam core stabilize toy shape over time

Locks high-loft fill in place, preventing internal shifting

Reduces stress on seams, minimizing sagging or deformation

Maintains volume and silhouette even after repeated use or washing

Lowers return rates from misshapen products

Enhances durability and perceived product quality in-store and post-purchase

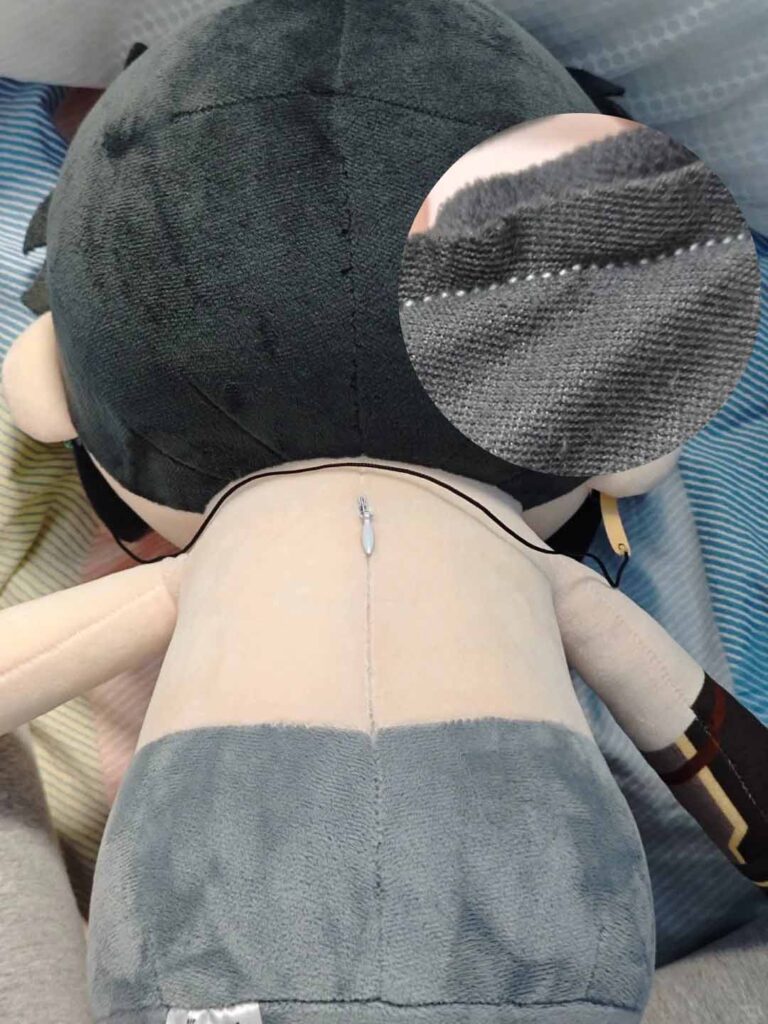

Reinforced Seam Architecture

Double-needle stitching at high-tension areas like limbs and joints

Hidden bartacks secure stress points and prevent thread breakage

Thread tension digitally controlled for strength without puckering

Bar-tacked ends prevent unraveling under repeated pulling

Increases tear resistance by up to 50% compared to standard seams

Extends product lifespan and reduces warranty issues

Supports confident marketing as “built for rough play”

Zoned Filling Technology

Uses denser microfiber in the core (head & torso) for support

Applies softer hollow fiber in limbs for squeeze and flexibility

Heat-sealed internal dividers prevent fill migration between zones

Maintains intended soft/hard contrast over long-term use

Enhances sensory experience and tactile comfort

Ensures visual and functional consistency after repeated washes

Handpick Soft Fabrics for Custom Toys

From premium feel to safety compliance, every Kinwin fabric is tested to meet international toy standards and elevate your plush creations.

Modal Microfiber Plush

Cuddle Fleece Knit

Anti-Pill Coral Fleece

French Terry Cotton Knit

Waffle Terry Fabric

Cotton Twill Canvas

PU Leatherette Panels

Jacquard Embossed Plush

Tencel Blend Fabric

Recycled PET Plush

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Select High-Quality Filling Materials Easily

Bean Pellet Filling

Our food-grade pellets come in four categories:

- Smooth PVC Pellets: Economical, smooth texture—widely used in collectible figurine plushies.

- Textured PE Pellets: Improved grip and weight—ideal for floor-sitting animals.

- Recycled Eco-Pellets: Sustainable option made from post-consumer plastics—appeals to green-focused clients.

- Natural Glass Beads: Premium weight and stability—used in luxury weighted lap pads and specialty dolls.

Pellet grades differ in weight, texture, and sustainability profile. You choose PVC for budget lines, PE for tactile grip, recycled pellets for eco credentials, or glass beads for premium heft. Typical uses include keychain toys, weighted comforters, and poseable plush figures.

EPP Bead Filling

Expanded polypropylene (EPP) beads are available in:

- Standard Bead: Lightweight, durable, and moisture-resistant—used in beanbag-style plush chairs.

- Round Premium Bead: Smoother feel and quieter movement—preferred for weighted sensory animals.

- Bead-Fiber Blend: Adds structure with softness—great for decorative plush cushions and novelty toys.

EPP beads provide moldable support without compaction over time. You can opt for pure beads for malleability, premium beads for a hush-quiet feel, or blends for shape and softness. Common in beanbag toys, floor pillows, and therapy plush.

Polyester Hollow Fiber

Our microfiber polyester hollow fiber comes in three tiers:

- Siliconized Grade A: Exceptionally resilient, maintains loft and bounce—ideal for high-end cuddly plush dolls.

- Standard Grade B: Cost-effective with good support and softness—perfect for mass-market teddy bears and cushions.

- Micro-Denier Grade C: Ultra-fine filaments for an exceptionally silky hand feel—used in luxury baby blankets and premium character plushies.

Each grade balances cost, resilience, and softness differently. You choose Grade A for superior shape retention, Grade B for everyday volume, or Grade C when ultra-soft touch is critical. Common applications include stuffed animals, pillow hybrids, and sensory toys.

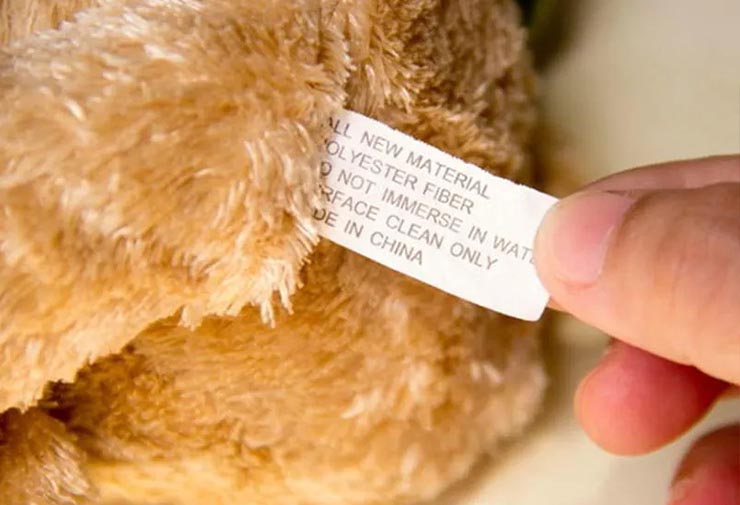

Logo Implementation Methods

Kinwin offers a range of professional logo application techniques to enhance brand recognition and value.

Embroidery

Woven Label

Heat Transfer

Screen Printing

Silicone Patch

PU Transfer

Laser Engraving

Hang Tag

Packaging Print

Metal Badge

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Offer Flexible Customization to Fit Your Brand

From signature shapes to packaging accents, we tailor every detail to match your vision and market identity.

Signature Silhouettes

Modify standard plush templates to create exclusive outlines or body shapes

Add brand-specific features like mascot ears, tail shapes, or character proportions

Supports licensing, co-branded campaigns, or original IP launches

Fabric & Texture Blending

Combine multiple fabric types in one design (e.g., sherpa, velboa, corduroy)

Select fabric textures that align with your target customer’s sensory expectations

Add surface contrast to enhance shelf impact and perceived value

Color Customization & Pantone Matching

Full-body or accent color customization using Pantone codes

Multi-zone color segmentation for more visual storytelling

Useful for holiday releases, seasonal SKUs, or event-specific drops

Functional Add-Ons

Integrate features like magnetic hands, Velcro attachments, or hidden pockets

Add playful interactivity such as sound chips, mirrors, or movement joints

Helps differentiate your plush line in competitive product categories

Tag & Accessory Personalization

Custom-branded hang tags, woven labels, care instructions, and header cards

Accessory items like ribbons, hats, or mini plush add-ons can be designed to match

Reinforces brand recall at point-of-sale and during unboxing

Packaging Variants & Gift Sets

Offer multiple packaging formats: window boxes, zipped pouches, kraft sleeves

Design multi-piece gift sets with themed inserts or seasonal themes

Supports premium positioning and gifting channels

See How Our Plush Production Process Works

Discover our streamlined, end-to-end plush manufacturing workflow in China—from concept and prototyping through stitching, filling, inspection, and packaging—to deliver custom plush toys that exceed quality and safety expectations every time.

1-Initial concept and design

2-Rapid prototyping

3-Material procurement

4-Pattern making and cutting

5-Professional sewing

6-Filling material

7-Quality Inspection

8-Brand Label

9-Package

10-Shipping

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Commit to Eco-Friendly Production Standards

1.Low-Waste Cutting & Fabric Optimization

Digital pattern software maximizes fabric yield with nested layouts

Off-cut materials are sorted and reused for smaller items or internal testing

Reduces landfill waste and improves cost efficiency for bulk orders

2.Water-Saving Dyeing & Finishing

Partnered mills use low-liquor dyeing systems and closed-loop rinsing

Adopts air-drying and low-temperature curing to reduce energy and water usage

All dyed fabrics comply with ZDHC, OEKO-TEX®, and REACH wastewater protocols

3.Green Energy & Emissions Management

Factory lighting powered by high-efficiency LED and solar panel supplementation

Machines regularly calibrated to minimize idle energy consumption

Emissions tracking integrated into production planning and annual reporting

4.Sustainable Packaging & End-of-Life Solutions

Packaging options include FSC-certified cartons and PLA-based biodegradable bags

Clients may opt into our plush toy take-back pilot for closed-loop reuse

Encourages responsible disposal, extends product lifecycle, and reduces environmental impact

Highlight Precision in Stitching and Seams

Computerized Stitch Calibration

PLC-controlled sewing machines automatically adjust stitch length, needle depth, and back-tack for each fabric

- Preset calibration profiles ensure consistent seam quality across mass production

- Eliminates human error and uneven stitching

- Prevents seam puckering and gaps for clean, secure joins

- Guarantees consistent appearance and durability across every unit

- Reduces defect rates and supports retailer expectations for uniform quality

Engineered Thread Selection & Tension Control

Each product has a matched thread type based on required strength, elasticity, and durability

- Core-spun polyester threads selected for UV resistance and wash durability

- Threads undergo tension testing before approval for production

- On-machine sensors monitor thread tension in real time

- Automatic alerts prevent tension inconsistencies or breakage

- Results in longer-lasting seams with excellent stretch recovery and laundering performance

Multi-Pass Reinforcement & Seam Finishing

Stress points like limbs and attachment zones get extra stitching: bar-tack or concealed zigzag passes

- Seam edges are folded under and blind-stitched to prevent exposed threads

- Ultrasonic trimming removes excess thread; heat-sealed ends lock threads securely

- Results in tear-resistant seams that maintain shape even under frequent use

- Clean finishing gives a polished, high-end appearance

- Enhances product lifespan and buyer confidence in durability

Have More Questions?

We’re happy to answer any questions you have about our products or working with our factory.

Showcase Tangible Benefits of Partnering with Us

Faster Product Launch Cycles

Cost Control with Transparent Quoting

Enhanced Brand Differentiation

Lower Risk with Low MOQs

Priority Fulfillment for Strategic Accounts

Real-Time Collaboration & Visibility

Anticipate Plush Trends Shaping Tomorrow’s Market

Plush toys are no longer just soft companions—they’re becoming multifunctional, purpose-driven, and experience-enhancing. Kinwin actively tracks consumer shifts to help brands stay one step ahead.

Multi-Sensory Enrichment Plush

- Toys that combine texture, sound, scent, and light for full sensory immersion

- Inclusion of light-up panels, crinkle fabric zones, and calming sound modules

- Soothing scent capsules (e.g. lavender or chamomile) embedded in core

- Ideal for mindfulness toys, bedtime routines, and developmental enrichment

Functional Plush for Everyday Use

- Dual-purpose plush items that merge play with practical application

- Plush toys doubling as travel pillows, storage pouches, or screen cleaners

- Built-in magnets or hooks for car, stroller, or desk integration

- Expands usage scenarios while encouraging daily brand exposure

Data-Driven Customization & Trend Responsiveness

- Using real-time data and seasonal trends to fuel plush development

- AI-powered demand analysis to spot trending themes and character traits

- Limited drops inspired by TikTok aesthetics, viral color palettes, or cultural events

- Enhances relevance and shortens concept-to-launch timeline for fast response

Find Answers in Our Comprehensive FAQ

We understand: ordering customized plush toys from overseas isn’t a small decision. That’s why we’ve answered your most common questions here—to save you time, reduce back-and-forth, and help you move forward with confidence.

1. Can I customize inner packaging (tags, inserts, wrap)?

Absolutely. We support fully customized inner packaging, including swing tags, care cards, QR code inserts, or printed tissue paper. You can submit your layout or request our design support.

2. Do you support blind dropshipping or third-party fulfillment?

Yes. We can ship directly to your fulfillment center or final destination with neutral or branded packing slips. Confidentiality is maintained throughout the process.

3. How to handle urgent replacement orders?

For old products with confirmed samples, we can arrange expedited production and support small batch replacement orders. Generally, replacement orders within 2,000 pieces can be delivered within 2-3 weeks.

4. How long do you keep molds or embroidery files?

We archive all digital and physical tools for at least 24 months after last use. If you reorder within that period, no setup fees will be recharged.

5. Can you help us localize plush features for different markets?

Yes. We regularly adapt SKUs for specific regions—such as heat-tolerant fabrics for the Middle East, bilingual labels for Canada, or eco-certified fills for Europe.

6. What happens if my shipment gets held at customs?

Our logistics team will assist in real-time with customs document re-submission or product clarification. All products come with harmonized HS codes and export clearance documentation.

7. Do you provide exclusive production rights?

For custom-designed characters or branded toys, we can sign exclusivity agreements by market, region, or sales channel. MOQs apply depending on the scope of exclusivity.

8. Can you accommodate seasonal launch schedules?

Yes. We help clients back-plan by season, providing design timelines and pre-booked slots for major launch windows (e.g., Christmas, Valentine’s Day, Back-to-School).

Still Have Questions?

We’re just one message away. Contact us and let’s build your next plush toy bestseller—together.

If You Can lmagine lt,We Will Create lt!

1.Tell Us What You Need

Tell us as specific as possible of your needs and share your idea.

2.Get Solution & Quote

We will work on the best solution according to yourrequirements,the specific quote will be provided within 24 hours.

3.Approve for Mass Production

We will start mass production after getting your approval.