Choosing the right plush fabric is crucial in stuffed animal production. It affects the toy’s softness, durability, and overall quality, ensuring an appealing and long-lasting product for consumers.

Plush fabric offers a soft, velvety texture with varying pile lengths and densities. High-quality fabric enhances comfort and resilience, while manufacturing methods and compliance standards ensure safety and customization flexibility.

Let’s explore the essential features and considerations for plush fabric in stuffed animal manufacturing.

1.What are the key characteristics of plush fabric used in stuffed animals?

Plush fabric is characterized by its dense, soft pile that creates a smooth, velvety surface. It is typically made from polyester fibers, chosen for their softness, durability, and color retention. The pile length and density influence the fabric’s texture and plushness.

Key traits include softness, durability, color vibrancy, and ease of cleaning, making plush fabric ideal for cuddly toys.

- Pile Length: Longer piles offer a fluffier feel but may reduce durability.

- Fiber Type: Polyester fibers dominate for softness and resilience.

- Weave Density: Tighter weave enhances strength and pile retention.

- Color Fastness: Important for vibrant, lasting colors through washing.

| Characteristic | Description | Impact on Toy Quality |

|---|---|---|

| Pile Length | Short to long | Softness vs durability |

| Fiber Material | Mostly polyester | Softness and resilience |

| Weave Density | Tight | Strength and shape retention |

| Color Fastness | High | Appearance over time |

Choosing the right balance is key to excellent plush fabric.

2.How does plush fabric quality impact the durability and feel of stuffed animals?

High-quality plush fabric improves both the tactile experience and longevity of stuffed animals. Softness encourages cuddling and comfort, while durability ensures the toy withstands play, washing, and wear.

Low-quality plush can pill, shed, or lose softness quickly, damaging brand reputation and customer satisfaction.

- Softness: Influences initial appeal and comfort.

- Durability: Affects lifespan under repeated use.

- Maintenance: Quality fabric resists pilling and matting after washing.

- Appearance: Maintains color and texture over time.

| Quality Aspect | High-Quality Plush | Low-Quality Plush |

|---|---|---|

| Softness | Silky, consistent | Rough, uneven |

| Durability | Withstands washing/play | Wears quickly |

| Maintenance | Easy to clean, no pilling | Pills and mats |

| Appearance | Vibrant, lasting color | Fades fast |

Investing in premium plush fabric ensures superior user experience.

3.Which types of plush fabric are most popular in the stuffed animal industry?

The stuffed animal industry frequently uses fabrics like minky, velboa, faux fur, and microplush. Each fabric offers unique textures suited to different toy designs and target markets.

Minky is renowned for its silky softness, velboa for durability and price, faux fur for realistic texture, and microplush for smooth, velvety surfaces.

- Minky: Soft, smooth, often used for baby toys.

- Velboa: Durable, short pile, ideal for mass-market toys.

- Faux Fur: Long pile, realistic look for animal replicas.

- Microplush: Fine, dense pile for luxury feel.

| Fabric Type | Texture | Best For | Price Range |

|---|---|---|---|

| Minky | Silky, smooth | Infant and baby plush | Medium-high |

| Velboa | Short, firm | Durable kids’ toys | Low-medium |

| Faux Fur | Long, realistic | Realistic animal plush | Medium-high |

| Microplush | Dense, soft | High-end plush | High |

Choosing fabric depends on desired look, feel, and cost.

4.How do manufacturing techniques influence the performance of plush fabric in toys?

Manufacturing steps like weaving, knitting, brushing, and finishing affect plush fabric quality. Brushing raises the pile, enhancing softness. Heat setting stabilizes the fabric to maintain shape and pile density.

Proper techniques ensure plush fabric performs well during sewing, stuffing, and usage, impacting toy durability and feel.

- Weaving/Knitting: Determines fabric base strength.

- Brushing: Raises pile, enhances softness.

- Shearing: Controls pile length for consistency.

- Heat Setting: Fixes fabric shape, reduces shrinkage.

| Manufacturing Step | Purpose | Effect on Plush Fabric |

|---|---|---|

| Weaving/Knitting | Base fabric creation | Strength and durability |

| Brushing | Raise and soften pile | Softness and plush feel |

| Shearing | Trim pile length | Uniform texture |

| Heat setting | Stabilize fabric | Shape retention |

Well-executed processes lead to premium plush fabric.

5.What safety and compliance standards apply to plush fabric for stuffed animals?

Plush fabrics must meet safety standards like ASTM F963, CPSIA in the US, and EN71 in Europe. These regulations limit harmful chemicals, ensure flame retardancy, and set quality benchmarks.

Certified fabrics provide assurance that stuffed animals are safe for children and compliant with global market requirements.

- Chemical Restrictions: Limits on heavy metals, phthalates.

- Flammability: Fabrics tested for fire resistance.

- Labeling: Clear safety information mandatory.

- Testing: Third-party labs verify fabric safety.

| Standard | Region | Key Requirements | Impact on Plush Fabric |

|---|---|---|---|

| ASTM F963 | USA | Chemical and flammability | Requires certified fabrics |

| CPSIA | USA | Lead and phthalates limits | Restricts fabric additives |

| EN71 | Europe | Safety in toys | Mandates tested materials |

| REACH | Europe | Chemical registration | Encourages eco-friendly fabric |

Compliance avoids recalls and builds brand trust.

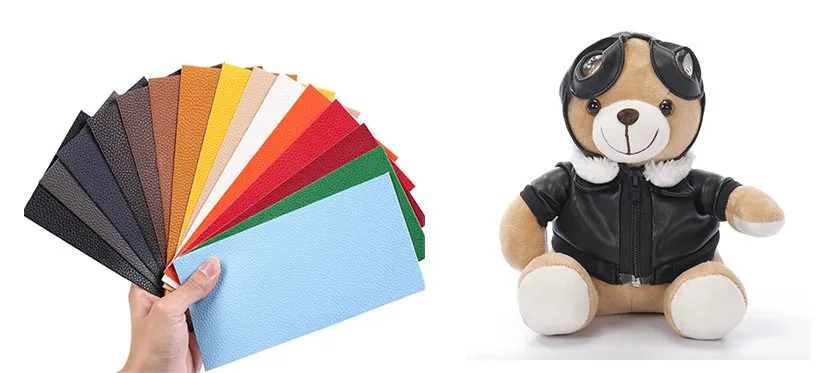

6.How does fabric selection affect customization and design possibilities for stuffed animals?

Fabric choice influences the ease and quality of printing, embroidery, and appliqué. Smooth fabrics like microplush accept detailed prints, while velboa is better suited for embroidery and patchwork.

Understanding fabric compatibility with decoration methods allows creating highly customized, visually appealing plush toys.

- Printing: Digital and sublimation printing need smooth, synthetic fabrics.

- Embroidery: Requires firm, low-pile fabrics for clear designs.

- Appliqué: Adds texture, needs sturdy fabric bases.

- Dyeing: Some fabrics absorb dyes better, affecting color vibrancy.

| Customization Method | Ideal Fabric Type | Effectiveness |

|---|---|---|

| Digital printing | Microplush, minky | High-detail reproduction |

| Embroidery | Velboa, short pile | Sharp, durable designs |

| Appliqué | Firm woven fabrics | Adds dimension |

| Sublimation dyeing | Polyester blends | Vibrant, long-lasting |

Right fabric choice enhances brand differentiation.

Conclusion

Choosing the perfect plush fabric is vital for soft toy quality, safety, and market appeal. Our expertise ensures your stuffed animals delight customers and meet industry standards.

For tailored plush fabric sourcing and custom plush solutions, contact [email protected] or visit Kinwin Plush Toys.