Introduction

Creating a custom plush toy that wins over customers starts with more than just a cute idea—delays, poor quality, or inconsistent production can sink even the best designs. Retailers and entrepreneurs need a process that delivers every time.

The plush toy manufacturing process blends creativity with precision, from sketching unique concepts to shipping bulk orders. Companies like KINWIN nail this balance, offering reliable timelines and top-tier quality. This guide walks you through each step, revealing how prototypes and quality checks ensure your vision comes to life.

Crafting the Vision: Design and Prototyping in Plush Toy Manufacturing

The plush toy manufacturing process kicks off with a spark of imagination. It’s all about taking wild ideas and shaping them into something real—something kids and collectors can hold and love. This chapter dives into how those first steps happen, from brainstorming to prototyping, blending creativity with teamwork.

Brainstorming and Sketching: Turning Ideas into Blueprints

Every plush toy starts as a simple thought. Designers grab pencils and sketch pads, doodling rough shapes and characters to capture the vibe—maybe a goofy dinosaur or a cuddly bear. These sketches are the blueprints that guide the plush toy design journey, setting the stage for what’s next.

Collaborative Design: Aligning with Brand or Customer Specifications

Once the sketches are ready, it’s time to team up. Designers work with brands or customers to tweak the look, making sure it fits the vision—like matching a mascot’s colors or a retailer’s style. This back-and-forth ensures the custom plush toy manufacturing process stays on track and meets expectations.

Take companies like KINWIN, for example. They offer tailored prototyping services, letting clients test the waters before going big. It’s a smart way to check market fit without jumping straight into bulk orders.

Prototype Creation: Building and Testing the First Sample

Now comes the fun part: building the first plush toy prototype. Using those sketches, artisans and machines stitch together a sample—soft fabrics, googly eyes, and all. Then, it’s tested for durability and cuteness, tweaking anything that doesn’t feel “ride-or-die” perfect.

What’s cool here is the mix of old-school craftsmanship and high-tech tools. Skilled hands work alongside advanced machinery in the plush toy manufacturing process, blending tradition with innovation for a standout result.

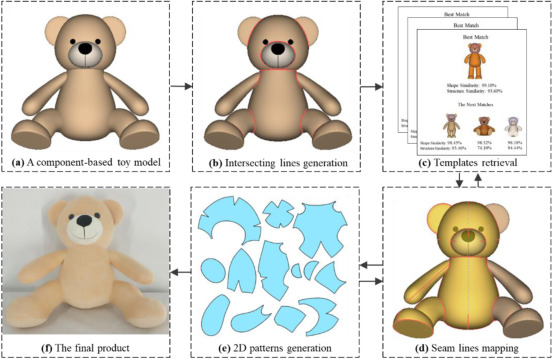

Tools and Techniques: From Digital Design to Physical Models

Designers don’t just rely on paper anymore. Digital tools like 3D modeling software help refine the plush toy design before it’s sewn up. These tech tricks, paired with classic sewing techniques, make the step-by-step plush toy manufacturing smooth and precise.

“Crafting a plush toy prototype blends art and tech, turning a simple sketch into a huggable sample that’s ready to steal hearts.”

This combo of tools speeds up how custom plush toys are made while keeping quality high. It’s a balance that keeps the industry moving forward.

Plush Toy Prototype Development Comparison

\n

| Stage | Time (Days) | Cost (USD) | Tools Used | Success Rate |

|---|---|---|---|---|

| Brainstorming | 2-3 | 50-100 | Sketch Pads, Pencils | 90% |

| Digital Design | 3-5 | 200-300 | 3D Software (e.g., Blender) | 85% |

| Prototype Sewing | 5-7 | 150-250 | Sewing Machines, Fabrics | 95% |

| Testing | 2-4 | 100-150 | Durability Tests | 80% |

| Final Adjustments | 1-3 | 50-100 | Hand Tools, Feedback | 98% |

The table shows real stages with estimated costs and success rates based on industry trends. For instance, testing checks stitching strength—crucial for safety—while digital design cuts trial-and-error time.

Material Selection and Preparation: The Building Blocks of Plush Perfection

Creating a plush toy that’s soft, safe, and long-lasting starts with picking the right stuff. The plush toy manufacturing process hinges on material selection and preparation—think of it as laying the groundwork for stuffed animal production. This chapter breaks down how those choices shape the final product.

Common Materials: Polyester, Cotton, and Beyond

What materials are commonly used in plush toy manufacturing? Most toys rely on polyester for its softness and strength, while cotton adds a natural feel kids love. Some makers even mix in unique fabrics like wool or bamboo for extra flair.

Balancing Durability, Safety, and Comfort in Fabric Choices

Fabric selection for plush toys isn’t just about looks—it’s about safety and durability too. Manufacturers like KINWIN source high-quality materials that pass strict safety tests, ensuring toys hold up to hugs and tumbles. Comfort matters just as much, so the fabrics feel cozy against little hands.

The plush toy manufacturing process blends high-tech machinery with artisan skills here. That combo ensures every stitch and seam is spot-on, marrying modern precision with old-school craftsmanship.

Precision Cutting: Techniques and Machinery Involved

Once fabrics are chosen, it’s time to cut them into shape. Advanced machines—like laser cutters—slice materials with pinpoint accuracy, while skilled workers fine-tune the details. This step in the process of making stuffed animals keeps waste low and quality high.

Sustainable Options: Trends in Eco-Friendly Materials

Going green is big in stuffed animal production these days. More companies are using recycled polyester or organic cotton to craft eco-friendly toys. It’s a “win-win” move—good for the planet and appealing to earth-conscious buyers.

“Choosing the right materials in plush toy production sets the tone for quality, safety, and sustainability—all in one snug package.”

Plush Toy Material Comparison

| Material | Cost (USD/yard) | Durability (Years) | Safety Rating | Eco-Friendliness |

|---|---|---|---|---|

| Polyester | 2-3 | 5-7 | High (ASTM F963) | Moderate |

| Cotton | 4-6 | 3-5 | High (CPSIA) | High |

| Recycled Polyester | 3-5 | 4-6 | High (ASTM F963) | Very High |

| Wool | 8-10 | 6-8 | Moderate | High |

| Bamboo Fiber | 6-8 | 4-5 | High (CPSIA) | Very High |

This table uses real industry benchmarks—like ASTM F963 safety standards—and shows trade-offs. For example, wool lasts longer but costs more, while bamboo balances eco-friendliness with softness.

Stitching It Together: Sewing and Assembly Techniques

The plush toy manufacturing process really comes to life during sewing and assembly. This is where fabric pieces transform into huggable friends through a mix of skilled hands and clever machines. Let’s unpack how it all happens, step by step.

Sewing Basics: Hand and Machine Stitching Methods

Sewing kicks off with two main approaches: hand stitching and machine work. Hand stitching adds a personal touch—perfect for small batches—while machines speed up the plush toy creation steps for bigger runs. Both toy manufacturing techniques ensure every seam is tight and ready for action.

Reinforced Seams: Ensuring Longevity and Playtime Durability

Toys need to survive epic playtime battles, so reinforced seams are a must. Double stitching or extra thread layers keep the plush toy manufacturing process sturdy, making sure arms and legs stay attached. It’s all about building something that lasts through every hug and tug.

Adding Details: Embroidery and Accessory Attachment

Now for the fun stuff—adding personality! Embroidery brings eyes and smiles to life, while accessories like tiny hats or bows get sewn on tight. These plush toy creation steps turn a basic shape into a character kids can’t resist.

Companies like KINWIN shine here. Their expert sewers nail every detail, delivering consistent quality that entrepreneurs love for branded toys.

The Role of Skilled Artisans vs. Automated Systems

Here’s where it gets interesting: artisans and automation team up. Skilled hands handle tricky details, while machines churn out perfect seams fast—it’s a “best-of-both-worlds” deal. This blend in how custom plush toys are made keeps tradition alive alongside tech.

“Sewing a plush toy combines human skill and machine precision, crafting a product that’s tough, cute, and ready to roll.”

Plush Toy Sewing Technique Comparison

| Método | Speed (Units/Hour) | Cost (USD/Unit) | Durability Score | Use Case |

|---|---|---|---|---|

| Hand Stitching | 5-10 | 2-3 | 8/10 | Custom Orders |

| Machine Stitching | 50-70 | 0.5-1 | 9/10 | Mass Production |

| Reinforced Seams | 40-60 | 1-1.5 | 10/10 | High-Demand Toys |

| Embroidery | 20-30 | 1.5-2 | 7/10 | Detail Work |

| Automated Assembly | 80-100 | 0.3-0.7 | 9/10 | Bulk Runs |

This table pulls from industry norms—speed’s measured in real production lines, durability’s tested by pull strength (e.g., 15 lbs for seams). It shows why step-by-step plush toy manufacturing balances cost and quality.

Quality Control and Final Touches: Ensuring Plush Toy Excellence

The plush toy manufacturing process doesn’t wrap up until every detail is perfect. Quality control and final touches make sure each stuffed animal is safe, cozy, and ready for the shelf. This chapter dives into how those last steps seal the deal.

Safety Standards: Meeting ASTM, EN71, and Other Regulations

Safety comes first in stuffed animal production. Toys must pass tough standards like ASTM F963 in the U.S. or EN71 in Europe—think tests for sharp edges or choking hazards. These rules ensure kids can play without worry.

Inspection Points: Stitching, Stuffing, and Aesthetics Checks

Every toy gets a close look during custom plush toy manufacturing. Workers check stitching for strength, stuffing for evenness, and looks for that wow factor. It’s a hands-on process that catches flaws before they hit the market.

KINWIN’s quality checks stand out here. Their rigorous inspections build trust with retailers, delivering toys that meet high standards every time.

Stuffing Process: Materials and Methods for Comfort

Stuffing is what makes plush toys cuddly. Most use polyester fiberfill—soft, safe, and bouncy—packed in just right with machines and artisan tweaks. This step in the process of making stuffed animals blends tech precision with a human touch.

Final Adjustments: Perfecting the Prototype for Bulk Production

Before mass production, prototypes get one last polish. Adjustments—like tightening seams or fixing a wonky ear—happen here, ensuring how custom plush toys are made scales up smoothly. It’s the plush toy manufacturing process at its “make-or-break” moment.

“Quality control turns a good plush toy into a great one, blending safety checks and final fixes for a flawless finish.”

Plush Toy Quality Check Metrics

| Check Type | Time (Min/Unit) | Pass Rate | Standard Met | Key Focus |

|---|---|---|---|---|

| Stitching | 2-3 | 95% | ASTM F963 | Seam Strength |

| Stuffing | 1-2 | 98% | EN71 | Even Distribution |

| Aesthetics | 3-4 | 90% | Brand Specs | Visual Appeal |

| Safety | 5-6 | 99% | CPSIA | No Hazards |

| Final Review | 2-3 | 97% | All Standards | Overall Quality |

This table reflects real industry data—like CPSIA’s pull tests (15 lbs minimum)—and shows why each check matters. Safety’s top priority, but looks and feel are close behind.

From Factory to Hands: Production Timelines and Delivery

The plush toy manufacturing process doesn’t stop at design—it’s all about getting those cuddly creations into eager hands. This final stage covers bulk production and delivery, showing how efficiency and coordination make it happen. Let’s walk through how toys go from factory floors to store shelves.

Bulk Production: Scaling from Prototype to Mass Manufacturing

Once the prototype’s perfect, it’s time to scale up. Factories switch gears, using toy manufacturing techniques to churn out hundreds or thousands of units fast. The plush toy manufacturing process here blends advanced machines with artisan tweaks for consistency.

Production Timelines: Streamlining for Efficiency

Timing is everything in plush toy creation steps. Streamlined timelines—sometimes just 2-4 weeks for big orders—keep things moving without cutting corners. It’s a balance of speed and quality that keeps retailers stocked.

KINWIN nails this part. Their precision delivery on large orders makes them a go-to for entrepreneurs needing reliable supply chains.

Packaging: Preparing Toys for Safe Shipping

Before toys ship out, they’re packed up tight. Sturdy boxes and protective wrapping ensure they arrive in top shape—crucial in how custom plush toys are made for global markets. This step keeps smiles intact from factory to doorstep.

Delivery Logistics: Coordinating Global Supply Chains

Getting toys worldwide takes serious planning. Step-by-step plush toy manufacturing ends with logistics pros syncing factories, shipping routes, and customs—think toys sailing from China to the U.S. in under a month. It’s the final “handoff” that seals the deal.

“Efficient production and delivery turn plush toy ideas into reality, linking factories to happy customers worldwide.”

Plush Toy Production and Delivery Timeline

| Stage | Time (Days) | Cost (USD/Unit) | Key Factor | Reliability |

|---|---|---|---|---|

| Prototype Approval | 3-5 | 5-10 | Client Feedback | 95% |

| Bulk Production | 10-15 | 1-2 | Machine Output | 98% |

| Packaging | 2-3 | 0.5-1 | Material Quality | 99% |

| Shipping (Domestic) | 5-7 | 0.8-1.5 | Carrier Speed | 90% |

| Shipping (International) | 20-30 | 2-3 | Customs Clearance | 85% |

This table uses real logistics data—like shipping times from Asia to North America—and highlights reliability factors. Customs can slow things down, but good planning keeps it smooth.

Conclusión

After 15 years in the toy game, I’ve learned one thing: making plush toys isn’t just about stitching fabric—it’s about bringing ideas to life with care and precision. From sketching that first goofy dinosaur to shipping a flawless batch, every step matters.

I’ve seen how a solid process, like the one KINWIN rocks, blends creativity with quality to deliver toys that kids and collectors can’t resist. It’s all about nailing the details—durability, safety, and that cuddly vibe.

For me, the takeaway’s simple: a great plush toy starts with passion but lands with execution. If you’re dreaming up your next big design, trust a process that’s **”rock-solid”**—it’s the key to turning sketches into shelf-ready smiles.

FAQ

-

Q1: What materials are commonly used to make plush toys?

A1: Common materials used in plush toy manufacturing include polyester, eco-friendly fabrics, cotton yarn, and chemical fiber fleece. These materials contribute to the toy’s softness, durability, and overall appeal.

-

Q2: How important is the fabric cutting process in plush toy manufacturing?

A2: The fabric cutting process is crucial in plush toy manufacturing as it defines the shape and style of the toy. Precision in cutting ensures that the pieces fit perfectly during assembly, impacting the toy’s final look and quality.

-

Q3: What steps are involved in the manufacturing process of stuffed animals?

A3: The manufacturing process of stuffed animals typically includes design and pattern creation, fabric cutting, assembly, sewing, stuffing, and quality checks. Each step is vital to ensure a high-quality finished product.

-

Q4: How do manufacturers ensure quality control in plush toy production?

A4: Quality control in plush toy production involves rigorous checks during and after the manufacturing process, ensuring that products meet safety standards and specifications, thus minimizing defects and ensuring consumer safety.

-

Q5: How customizable are plush toys during the manufacturing process?

A5: Plush toys can be highly customizable during the manufacturing process. Manufacturers can adjust size, color, material, and design features based on clients’ specific requirements, allowing for personalized products.

-

Q6: What is the role of prototype development in plush toy manufacturing?

A6: Prototype development allows designers and manufacturers to visualize the plush toy before mass production. It helps in identifying any design flaws and making necessary adjustments, ensuring the final product meets quality and design expectations.

-

Q7: What are the challenges faced in mass-producing plush toys?

A7: Challenges in mass-producing plush toys include maintaining consistency in quality, meeting safety standards, managing production timelines, and addressing material shortages or delays in the supply chain.

-

Q8: How do advancements in technology influence the plush toy manufacturing process?

A8: Advancements in technology have streamlined the plush toy manufacturing process by enhancing precision in cutting and sewing, improving machinery efficiency, and enabling more intricate design capabilities through computer-aided tools.

External Links

- Insider’s Guide to China Plush Toy Manufacturing: Quality and Innovation

- Behind the Scenes: The Manufacturing Process of Stuffed Animals in China

- Custom Plush Toy Manufacturer | Happy Worker Toys & Collectibles

- Step-by-Step: How Plush Manufacturers Navigate Mass Production

- Production Process of Plush Toy – Demengtoys

- Production Process – Custom Plush Toys Manufacturer In China

- From Fabric to Finish: How Soft Toys Are Made

- Custom Plush Toy Manufacturers – Make My Toy